What's Happening?

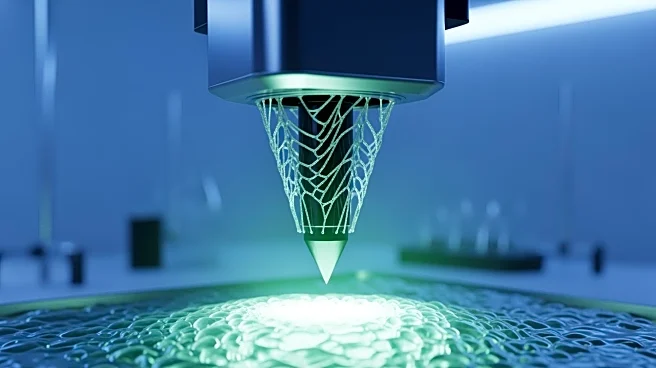

A research team from McGill University in Canada has innovatively repurposed mosquito mouthparts to create ultra-fine nozzles for 3D printers. This technique, termed '3D necroprinting,' utilizes the severed

mouthparts of female mosquitoes to fabricate extremely tiny structures, addressing the limitations of commercially available 3D printer nozzles. The smallest commercial nozzle has an inner diameter of 35 micrometers and is costly, whereas the mosquito-based nozzles measure just 20 micrometers and can be produced for less than $1 each. This process is scalable and can be integrated with existing 3D printers. The biological origin of these nozzles allows them to have a relatively long lifespan, with about 30% beginning to degrade after two weeks, but they can be stored frozen for up to a year.

Why It's Important?

This development could significantly impact the field of medical technology, particularly in the production of transplant organs. The ability to print ultra-fine structures using bioink like 'Pluronic F-127' offers promising methods for manufacturing artificial organs, including scaffolds for biological tissues such as blood vessels. The innovation highlights the potential of bio-inspired engineering, where natural designs are leveraged to overcome technological limitations. This could lead to more cost-effective and efficient production processes in the medical industry, potentially reducing the costs associated with organ transplants and increasing accessibility for patients.

What's Next?

The research team plans to further explore the applications of this technology in the medical field, particularly in the production of artificial organs. As the technique is easily scalable, it could be adopted by other research institutions and companies looking to innovate in the field of bioprinting. The integration of biological components into mechanical systems may also inspire new avenues of research in robotics and sensor technology, as seen in other examples like drones using moth antennae for smell detection.

Beyond the Headlines

This research underscores the growing trend of biomimicry in engineering, where natural systems inspire technological advancements. The ethical implications of using biological materials in technology could spark discussions about sustainability and the balance between innovation and ecological impact. Additionally, the long-term effects of integrating biological components into mechanical systems may lead to new standards and regulations in the industry.