What's Happening?

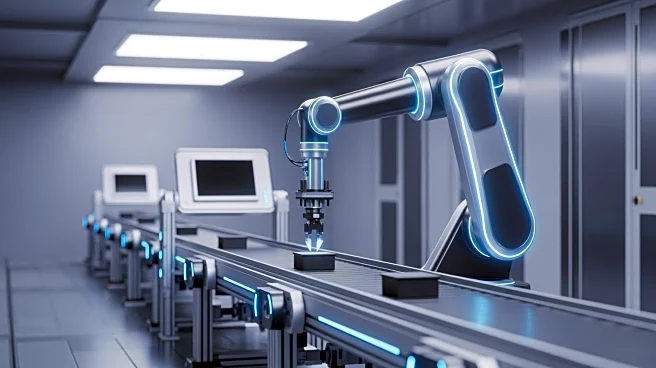

AI is being increasingly integrated into manufacturing operations to enhance productivity and efficiency. Technologies such as machine learning and agentic AI are being used to automate tasks, improve

quality control, and optimize production schedules. AI systems are capable of detecting product defects and process deviations in real-time, allowing for immediate interventions to prevent disruptions. This integration is transforming traditional manufacturing processes, making them more adaptive and responsive to changing demands.

Why It's Important?

The adoption of AI in manufacturing is crucial for maintaining competitiveness in a rapidly evolving industry. By automating routine tasks and improving decision-making processes, AI helps manufacturers reduce costs and increase output. This technological shift is particularly important for industries facing labor shortages and rising production costs. The ability to quickly adapt to market changes and consumer demands can provide a significant advantage in the global marketplace.

What's Next?

As AI technologies continue to advance, manufacturers are likely to explore more complex applications, such as predictive maintenance and supply chain optimization. The integration of AI with IoT devices could further enhance data collection and analysis, leading to more informed business decisions. Companies may also invest in AI-driven research and development to innovate new products and processes, potentially reshaping the manufacturing landscape.

Beyond the Headlines

The widespread use of AI in manufacturing raises ethical and legal considerations, particularly regarding workforce displacement and data privacy. Companies must navigate these challenges carefully, ensuring that AI implementation does not compromise employee rights or consumer trust. Additionally, the reliance on AI systems necessitates robust cybersecurity measures to protect sensitive data from potential breaches.