What is the story about?

What's Happening?

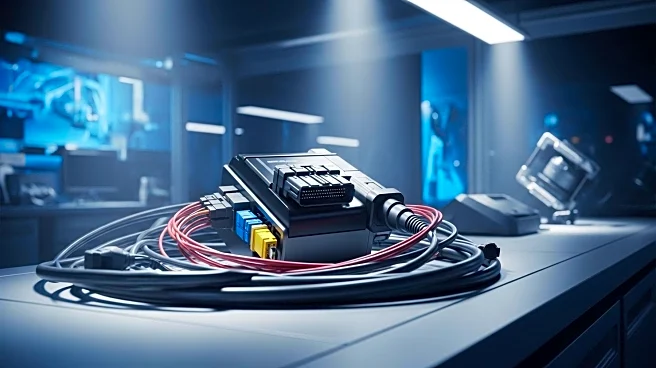

RemotiveLabs has announced a collaboration with Kvaser to integrate their hardware into the RemotiveTopology simulation platform. This integration allows developers to bridge Software-in-the-Loop (SIL) and Hardware-in-the-Loop (HIL) testing seamlessly. Kvaser, known for its cost-efficient and robust machine-to-machine connectivity solutions, provides cross-platform drivers and development tools that enhance network analysis and interfacing. The combined solution enables software teams to develop and test vehicle functions using both virtual setups and real hardware nodes, facilitating targeted testing without requiring full system setups.

Why It's Important?

The integration of Kvaser hardware with RemotiveTopology offers significant benefits for the automotive industry, including faster iteration, scalability, and lower barriers to entry for testing. By allowing developers to run most integration tests virtually and reserve costly HIL rigs for final confirmation, the solution reduces time and costs associated with vehicle development. This approach also promotes collaboration across teams and enables hybrid testing from day one, which is crucial for modern vehicle development processes. The integration supports the industry's shift towards more agile and cost-efficient testing methods.

What's Next?

RemotiveLabs and Kvaser will continue to demonstrate the capabilities of their integrated solution at industry events, such as the IAA. As the automotive industry increasingly adopts virtual and hybrid testing methods, more companies may explore similar integrations to enhance their development workflows. The collaboration could lead to further innovations in vehicle testing, potentially influencing industry standards and practices. Developers and test teams will likely benefit from ongoing improvements in the integration of virtual and hardware testing environments.

Beyond the Headlines

The integration of Kvaser hardware with RemotiveTopology highlights the growing importance of flexible and cost-efficient testing solutions in the automotive industry. As companies seek to reduce development costs and improve testing accuracy, the collaboration may drive broader changes in how vehicle functions are developed and tested. Additionally, the integration could influence the adoption of new technologies and methodologies in the industry, potentially leading to more sustainable and efficient vehicle development processes.

AI Generated Content

Do you find this article useful?