What's Happening?

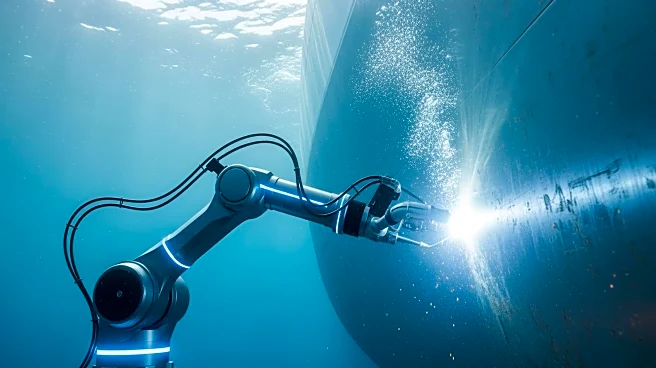

A research consortium led by the German Research Center for Artificial Intelligence (DFKI) has developed an innovative underwater welding robot designed to perform autonomous welding tasks. This development aims to address the shortage of skilled industrial

divers needed for underwater repairs of maritime infrastructure, such as port facilities and offshore structures. The project, known as MARIOW (Maritime AI-Guided & Remote Operated Welding), is funded by the Federal Ministry for Economic Affairs and Energy (BMWE). The system integrates artificial intelligence, sensor technology, and a robotic arm to execute precise and repeatable welding tasks at depths of up to 6,000 meters. The robot's AI capabilities include determining optimal welding paths using high-resolution images from a stereo camera system. This advancement is expected to relieve divers from physically demanding and risky tasks while ensuring more uniform weld seams.

Why It's Important?

The introduction of AI-driven underwater welding robots represents a significant technological advancement in maritime maintenance. By automating the welding process, the system addresses the growing demand for underwater repairs, which currently exceeds the availability of skilled divers. This innovation not only enhances safety by reducing the need for human divers in hazardous environments but also improves the efficiency and precision of underwater welding tasks. The potential for widespread adoption of such technology could lead to significant cost savings and operational efficiencies in the maritime industry. Additionally, the ability to perform maintenance tasks autonomously could extend the lifespan of maritime infrastructure and reduce downtime, benefiting industries reliant on these structures.

What's Next?

The consortium plans to further develop the MARIOW system by focusing on practical applications in real-world maritime environments, such as harbor basins. Future projects will address challenges posed by saltwater, currents, and waves, which require adjustments to the existing system. The integration of a laser system to remove welding slag is also planned. These enhancements aim to improve the quality of weld seams and ensure the system's reliability under varying environmental conditions. As the technology matures, it could see broader implementation across the maritime industry, potentially setting new standards for underwater maintenance practices.