What's Happening?

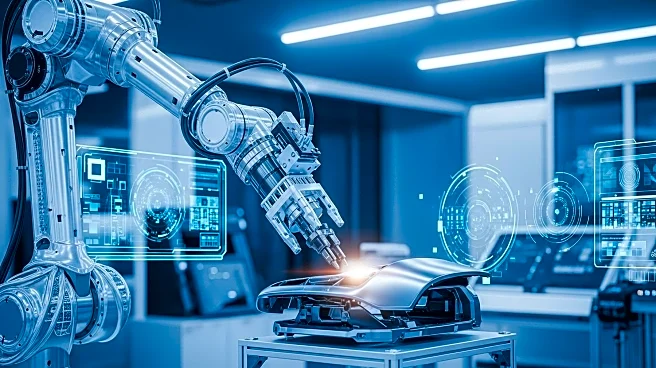

Machina Labs has announced a new robotic approach to automotive body manufacturing that aims to enable vehicle makers to produce customized vehicles at mass-production prices. The Los Angeles-based company, founded in 2019, has developed the RoboCraftsman platform, which integrates advanced robotics and AI-driven process controls. This technology allows for the rapid manufacturing of complex metal structures for aerospace, defense, and automotive applications. The traditional method of using large, expensive dies and presses is replaced by Machina Labs' system, which eliminates the need for dedicated tooling per model variation. This innovation promises lower project capital, reduced storage needs, and faster production changeovers. The company has also partnered with Toyota Motor North America to pilot this technology, with strategic investment from Woven Capital, Toyota's venture investment arm.

Why It's Important?

The introduction of Machina Labs' technology could significantly impact the automotive industry by making vehicle customization more accessible and affordable. Traditionally, high-volume manufacturing has limited the variation in vehicles due to the high costs and time associated with changing production tools. By eliminating the need for large dies and enabling on-demand part production, Machina Labs' approach could reduce costs and increase flexibility in manufacturing. This development aligns with the growing consumer demand for personalized products and could lead to a shift in how vehicles are designed and produced. The partnership with Toyota highlights the potential for this technology to be integrated into mainstream automotive production, potentially setting a new standard for customization in the industry.

What's Next?

Machina Labs plans to continue integrating its systems into automotive production over the next year, with the goal of scaling up to produce thousands of vehicles. The company aims to bring the benefits of customization, previously available only to the wealthy, to a broader market. As the pilot project with Toyota progresses, the industry will be watching closely to see how this technology can be applied to achieve automotive-grade quality and throughput in low-volume manufacturing. The success of this initiative could encourage other automakers to adopt similar technologies, further transforming the landscape of vehicle manufacturing.

Beyond the Headlines

The shift towards AI-powered manufacturing represents a broader trend in the industry towards more efficient and flexible production methods. This technology not only addresses the demand for customization but also offers potential environmental benefits by reducing waste associated with traditional manufacturing processes. Additionally, the ability to work with new alloys like titanium and nickel could open up new possibilities for vehicle design and performance. As the industry moves towards more personalized and sustainable production, Machina Labs' approach could play a pivotal role in shaping the future of manufacturing.