What's Happening?

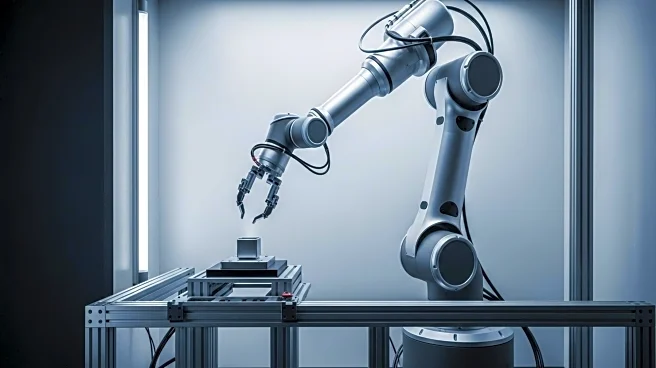

South Coast Robotics, a Fanuc authorized system integrator, has developed an innovative automation solution for a home-care products manufacturer facing space constraints. The company utilized inverted six-axis robots and a gravity-fed tray system to enhance packaging efficiency. This approach increased throughput by 20% and reduced labor by 66.7%. The system includes a custom rotating pneumatic mechanical gripper capable of rotating 360 degrees, making four picks and four places per cycle at a rate of 36 parts per minute, operating continuously. Strategic component placement, such as IP67-rated valve manifolds mounted directly on machines, helped reduce control cabinet size and commissioning costs.

Why It's Important?

The implementation of this automation system is significant for the manufacturing industry, particularly for companies facing spatial limitations. By optimizing space and increasing efficiency, South Coast Robotics' solution allows manufacturers to maintain high productivity levels without the need for extensive facility modifications. This can lead to cost savings and improved operational efficiency, providing a competitive edge in the market. The reduction in labor requirements also highlights the growing trend towards automation in manufacturing, which can lead to shifts in workforce dynamics and necessitate new skill sets among employees.

What's Next?

As automation continues to evolve, manufacturers may increasingly adopt similar systems to address space and efficiency challenges. South Coast Robotics' success could encourage other companies to explore innovative automation solutions, potentially leading to broader industry changes. The focus on rapid changeover capabilities to accommodate multiple stock keeping units (SKUs) suggests that manufacturers will continue to prioritize flexibility and adaptability in their operations.

Beyond the Headlines

The ethical implications of increased automation in manufacturing include potential job displacement and the need for workforce retraining. Companies may need to consider how to balance technological advancements with social responsibility, ensuring that employees are supported through transitions and equipped with the necessary skills for new roles.