What's Happening?

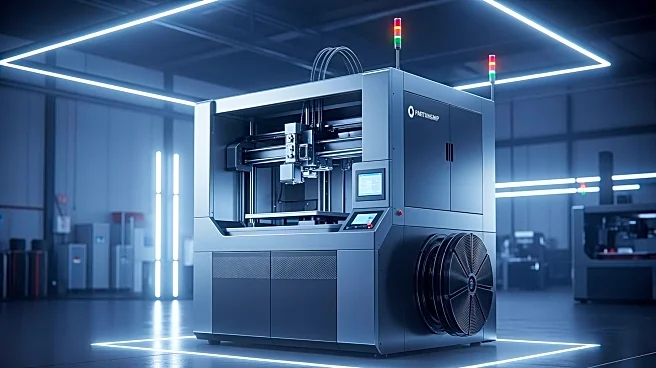

Sixpenny Additive, a newly launched Canadian metal additive manufacturing company, has been appointed as the first distributor and integration partner for Meltio's wire-laser metal 3D printing systems

in Canada. Meltio's technology, known for its wire-laser directed energy deposition (DED), allows manufacturers to produce dense metal parts using cost-effective welding wire. This partnership will enable Sixpenny Additive to offer system sales, integration, service, support, and application development to Canadian manufacturers. The collaboration aims to reduce costs, shorten lead times, and facilitate the production of parts that were previously challenging with conventional methods.

Why It's Important?

The partnership between Sixpenny Additive and Meltio is significant for the Canadian manufacturing industry as it introduces advanced metal 3D printing technology that can enhance production capabilities. This technology is particularly beneficial for industries such as automotive and aerospace, which require reliable and cost-effective solutions for producing and repairing metal parts. By providing local expertise and support, Sixpenny Additive can help manufacturers adopt this technology seamlessly, potentially leading to increased competitiveness and innovation within the sector.

What's Next?

Sixpenny Additive will focus on integrating Meltio's technology into Canadian manufacturing processes, offering training and technical assistance to ensure effective adoption. As the partnership progresses, it is expected to expand the availability of Meltio's 3D printing solutions across various industries, potentially leading to new product development and increased market presence for both companies.

Beyond the Headlines

The introduction of Meltio's wire-laser DED technology in Canada could lead to broader implications for the manufacturing industry, including shifts in production methods and supply chain dynamics. As more companies adopt this technology, there may be increased demand for skilled workers in additive manufacturing, prompting educational institutions to offer specialized training programs.