What's Happening?

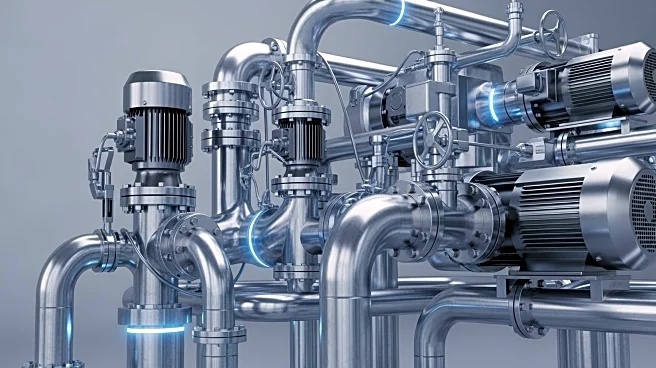

Intelligent fluid management is emerging as a practical entry point for manufacturers aiming to adopt Industry 4.0 practices. This approach involves real-time monitoring of lubricants and coolants, which are crucial for machine reliability and productivity.

Traditionally, fluid management has been a reactive process, leading to unplanned downtime and increased costs. However, advancements in real-time monitoring are transforming this into a proactive strategy, allowing for predictive maintenance and optimized fluid use. This shift not only reduces waste and costs but also enhances machine uptime and product quality.

Why It's Important?

The adoption of intelligent fluid management is significant for the manufacturing sector as it offers a scalable and low-barrier entry into digital transformation. By moving from reactive to data-driven maintenance, manufacturers can achieve cost savings, improve product quality, and reduce environmental impact. This approach also enhances asset reliability and optimizes resource use, which is crucial in an industry where margins are tight and customer expectations are high. Manufacturers who adopt these practices early can position themselves as leaders in reliability-driven manufacturing.

What's Next?

Manufacturers are encouraged to progressively adopt intelligent fluid management systems, starting with simple alert systems and moving towards full integration with enterprise maintenance software. This gradual approach allows them to build confidence and capture incremental benefits. As more manufacturers embrace this technology, it is expected to become a standard practice, driving further innovation and efficiency in the industry.

Beyond the Headlines

The shift towards intelligent fluid management also has environmental implications. By reducing waste and optimizing fluid use, manufacturers can lower their environmental footprint. This aligns with broader industry trends towards sustainability and responsible resource management. Additionally, the data-driven approach can enhance supply chain resilience, a critical factor in today's global manufacturing landscape.