What's Happening?

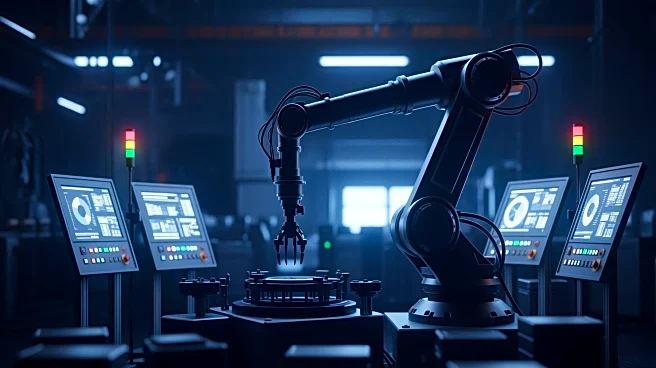

A significant shift in manufacturing is occurring with the rise of 'dark factories,' which are highly automated facilities requiring minimal human presence. These factories leverage advanced robotics and

automation technologies to operate without standard lighting, relying instead on specialized lighting systems for machine vision. The trend is driven by global labor shortages, rising human resource costs, and decreasing costs of advanced automation. Companies like Tesla, GE, and Intel are leading the way in implementing these technologies, aiming to enhance efficiency and reduce errors in production processes.

Why It's Important?

The emergence of 'dark factories' represents a pivotal moment in industrial automation, potentially transforming the manufacturing landscape. By reducing reliance on human labor, these facilities can lower operational costs and increase production efficiency. This shift could lead to a resurgence in domestic manufacturing, as companies capitalize on automation to compete globally. However, it also raises concerns about job displacement and the need for workers to adapt to new roles overseeing automated systems. The integration of AI and machine learning in these factories further underscores the importance of digital transformation in modern manufacturing.

What's Next?

As 'dark factories' continue to gain traction, companies may increasingly invest in automation technologies to remain competitive. This could lead to further advancements in AI-driven decision-making and predictive maintenance, optimizing factory operations. Stakeholders, including policymakers and industry leaders, may need to address the implications of reduced human labor in manufacturing, potentially focusing on retraining programs and workforce development to support displaced workers. The ongoing evolution of communication technologies like 5G and 6G will also play a crucial role in enabling seamless integration of automated systems.

Beyond the Headlines

The rise of 'dark factories' may have broader implications for global supply chains, as companies seek to streamline operations and reduce dependency on human labor. Ethical considerations regarding job displacement and the environmental impact of increased automation could become more prominent. Additionally, the shift towards automation may influence cultural perceptions of manufacturing, as traditional factory roles evolve to accommodate new technologies. Long-term, this trend could redefine the relationship between humans and machines in industrial settings.