What's Happening?

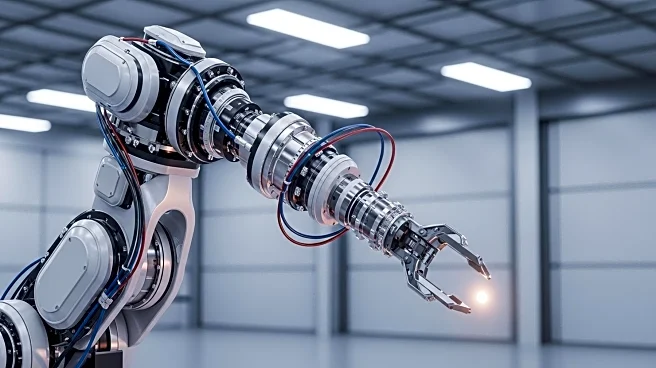

Flexxbotics has released an updated version of its FlexxCore robotics software, designed to improve efficiency in manufacturing environments. The software now includes enhanced capabilities for robotic machine tending, quality control, and production lines. It allows robots to operate multiple machines with various operations for different part SKUs, featuring improved robot awareness and parallelized data pipelines. The update also introduces greater data granularity and work order changeovers that detect order completion, updating part properties for subsequent orders. This advancement supports unattended robotic production, facilitating 'lights out' manufacturing processes.

Why It's Important?

The enhancements to FlexxCore software represent a significant advancement in manufacturing technology, potentially increasing productivity and reducing labor costs. By enabling robots to manage multiple machines and operations, manufacturers can streamline processes and improve efficiency. This could lead to cost savings and increased competitiveness in the manufacturing sector. The ability to conduct 'lights out' manufacturing—where production continues without human intervention—could revolutionize factory operations, allowing for continuous production and reduced downtime.

What's Next?

Manufacturers may begin integrating the updated FlexxCore software into their operations, potentially leading to widespread adoption of 'lights out' manufacturing practices. As companies implement these technologies, they may experience shifts in workforce dynamics, with a greater emphasis on technical skills and robot management. Flexxbotics may continue to refine and expand its software capabilities, responding to industry needs and technological advancements.