What is the story about?

What's Happening?

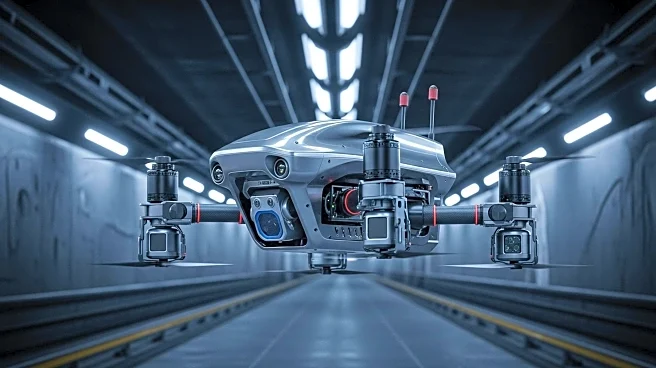

A new mobile inspection system for metro tunnels has been developed, integrating high-precision laser scanners, CCD cameras, and GNSS/IMU positioning sensors. This system is designed to improve the accuracy and efficiency of tunnel inspections by collecting comprehensive data on tunnel surfaces. The equipment is vehicle-mounted and electrically driven, allowing for quick assembly and disassembly. It can carry multiple inspection personnel and is compatible with various tunnel shapes and sizes.

Why It's Important?

The integration of multiple sensors in tunnel inspection equipment represents a significant advancement in infrastructure maintenance technology. This system can potentially reduce inspection times and improve the accuracy of data collected, leading to better maintenance decisions and enhanced safety for metro systems. The ability to quickly assemble and disassemble the equipment increases operational efficiency, which is crucial for minimizing disruptions in metro services.

What's Next?

Further development and deployment of this technology could lead to widespread adoption in metro systems worldwide, improving infrastructure management and safety. The data collected by the system may be used to develop predictive maintenance models, reducing the risk of tunnel failures and service interruptions. Collaboration with metro authorities could enhance the system's capabilities and integration into existing maintenance protocols.

Beyond the Headlines

The use of advanced sensors and data collection methods in infrastructure inspection highlights the growing importance of technology in urban planning and maintenance. This development could lead to more sustainable and efficient urban transportation systems, reducing the environmental impact of metro operations. The technology may also inspire innovations in other areas of infrastructure management, such as road and bridge inspections.