What's Happening?

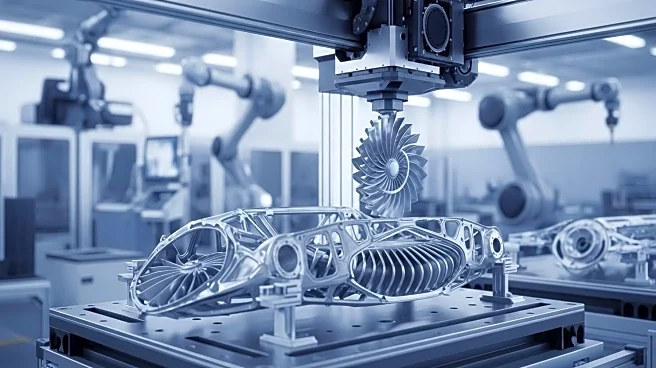

Spectrum Networks, LLC and ALOFT AeroArchitects are leveraging Markforged's additive manufacturing technology to produce certified parts for VIP and government aircraft. Using Markforged's FX10 platform and Continuous Fiber Reinforcement (CFR) technology,

they are able to design and manufacture replacement lighting and interior parts in weeks rather than months. This approach addresses challenges in sourcing parts for legacy systems during maintenance cycles, which can take aircraft out of service for extended periods. The precision-engineered components are installed by ALOFT AeroArchitects, ensuring reliability for aircraft transporting world leaders and governments.

Why It's Important?

The use of Markforged's additive manufacturing technology by Spectrum Networks and ALOFT AeroArchitects is a significant development in the aerospace industry. It demonstrates the potential of 3D printing to revolutionize the production of aircraft parts, reducing lead times and enhancing operational readiness. This technology allows for rapid modernization of aircraft interiors, which is crucial for maintaining the functionality of fleets serving high-profile clients. The ability to produce parts with unmatched precision and traceability also accelerates regulatory acceptance, potentially setting new standards for safety and quality in the sector.

What's Next?

As the collaboration between Spectrum Networks and ALOFT AeroArchitects continues, it may lead to broader adoption of additive manufacturing in the aerospace industry. This could result in more efficient supply chains and reduced downtime for aircraft undergoing maintenance. The success of this initiative might encourage other companies to explore similar technologies, further integrating 3D printing into the production processes for aerospace components. Regulatory bodies may also update standards to accommodate the advancements in additive manufacturing.