What's Happening?

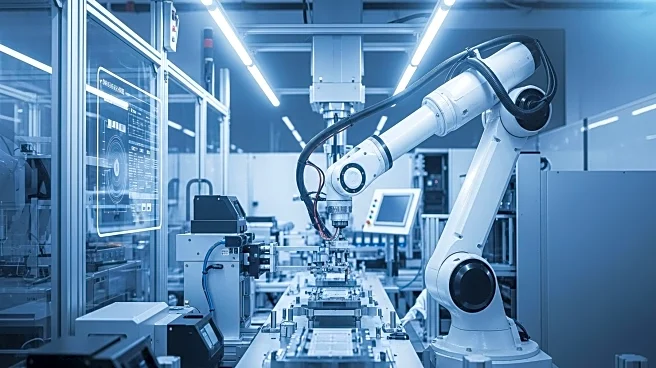

Manufacturers are increasingly adopting consumer-driven manufacturing models, which focus on real-time consumer demand and feedback to guide production decisions. This approach contrasts with traditional manufacturing, which relies on forecasts and historical data. According to Liya Getachew, principal at Sendero Consulting, consumer-driven manufacturing operates as a pull system, responding to live demand signals and producing goods only when and where they are needed. This shift requires manufacturers to build agile production lines, leverage consumer insights, and utilize technology and data to capture and process real-time information. The Internet of Things (IoT) plays a crucial role in enabling companies to personalize and make faster decisions. Operational agility and a collaborative mindset among cross-functional teams are also essential for this transformation.

Why It's Important?

The shift towards consumer-driven manufacturing is significant as it allows manufacturers to be more responsive to market changes and consumer preferences, potentially reducing waste and increasing efficiency. By aligning production closely with actual demand, companies can optimize inventory levels, minimize overproduction, and enhance customer satisfaction. This approach also supports the trend towards customization and personalization in consumer products, which can be a competitive advantage in the marketplace. The integration of technology, such as AI and IoT, further enhances the ability to predict disruptions, optimize operations, and identify emerging trends, positioning manufacturers to better navigate the complexities of modern supply chains.

What's Next?

As manufacturers continue to adopt consumer-driven models, the focus will likely be on further integrating advanced technologies and enhancing operational flexibility. Companies may invest in smart factories, modular systems, and digital twins to enable rapid adaptation to changing demands. The development of real-time data platforms and predictive analytics tools will be crucial in supporting these efforts. Additionally, fostering a culture of collaboration and innovation within organizations will be key to empowering teams to make swift, informed decisions. As the industry evolves, manufacturers that successfully implement these strategies may gain a competitive edge in the global market.

Beyond the Headlines

The transition to consumer-driven manufacturing may also have broader implications for the workforce and supply chain dynamics. As companies prioritize agility and responsiveness, there may be a shift in skill requirements, with a greater emphasis on data analysis, technology management, and cross-functional collaboration. This could lead to new training and development opportunities for employees. Furthermore, the increased reliance on real-time data and technology may raise concerns about data privacy and security, necessitating robust measures to protect sensitive information. The move towards more sustainable and efficient production practices could also contribute to environmental benefits, aligning with growing consumer and regulatory demands for eco-friendly solutions.