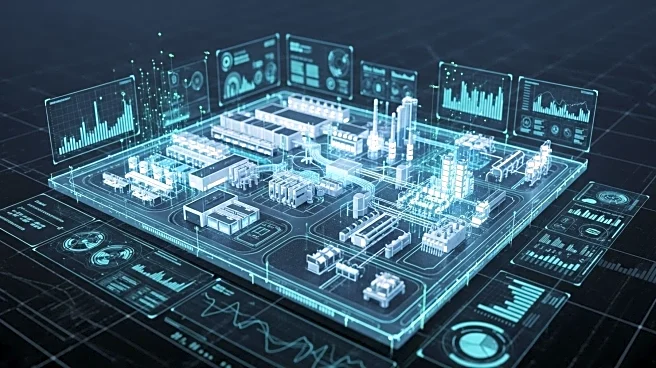

What's Happening?

Manufacturers are increasingly adopting digital twins to modernize existing brownfield factories without the need for complete equipment replacement. Digital twins provide virtual simulations of products and processes, enabling manufacturers to test and optimize automation systems before implementing physical changes. This approach allows for step-by-step integration of automation with existing machinery, enhancing efficiency and productivity. Collaborative robots, or cobots, are also being introduced to bridge the gap between manual and automated work, supporting workers by handling repetitive tasks. Virtual commissioning and industrial metaverse training further reduce costs and risks by allowing manufacturers to trial new systems and train robots in virtual environments.

Why It's Important?

The adoption of digital twins and cobots in manufacturing is crucial for maintaining competitiveness in a rapidly evolving industry. By modernizing brownfield factories, manufacturers can improve operational efficiency, reduce costs, and enhance worker job quality. This approach also allows for greater flexibility and adaptability in production processes, which is essential in responding to changing market demands. The integration of AI-powered tools further amplifies the impact of automation, increasing accuracy and enabling real-time optimization. As manufacturers face challenges such as rising operational costs and a tight labor market, these technologies offer a sustainable solution to drive growth and profitability.

What's Next?

Manufacturers are expected to continue leveraging digital twins and AI to further enhance automation systems. The industrial metaverse will play a significant role in accelerating robot training and programming, providing immersive virtual environments for robots to develop problem-solving skills. As these technologies become more integrated into factory operations, manufacturers will be able to anticipate equipment failures and optimize performance in real-time, minimizing costly downtimes. The ongoing adoption of these innovations will likely lead to more resilient and adaptive manufacturing processes, positioning companies to better navigate future industry challenges.

Beyond the Headlines

The shift towards digital twins and automation in manufacturing raises important ethical and cultural considerations. As factories become more automated, there is potential for job displacement, necessitating strategies for workforce retraining and upskilling. Additionally, the increased reliance on AI and digital technologies may lead to concerns about data privacy and security. Manufacturers will need to address these issues to ensure responsible and sustainable implementation of these technologies. The long-term impact of digital transformation in manufacturing could also influence broader economic and societal shifts, as industries adapt to new technological paradigms.