What's Happening?

Air France Industries KLM Engineering & Maintenance (AFI KLM E&M) has completed the industrialization of CFM International Leap engines at its upgraded test cells in Paris and Amsterdam. The company announced this development at the MRO Europe event in London,

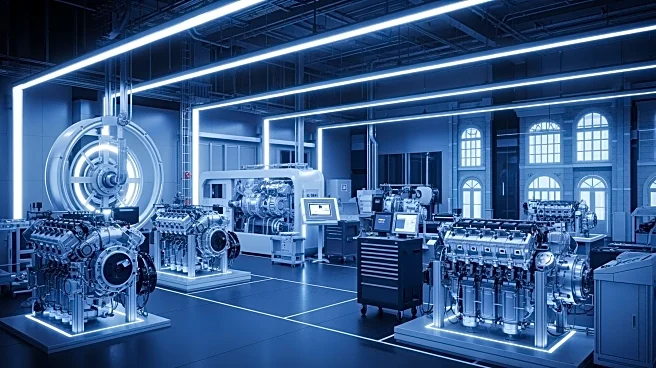

highlighting the new capabilities for testing Leap-1A and 1B engines. These engines power Airbus A320neo and Boeing 737 MAX aircraft, respectively. The advanced test cell facilities are equipped to handle high-bypass, high-thrust engines under real-world conditions, providing precise diagnostics and performance validation. This upgrade aims to enhance turnaround times and reduce logistical complexities for airline operators.

Why It's Important?

The expansion of testing capabilities for Leap engines is significant for the aviation industry, particularly for airlines operating modern narrowbody fleets. By improving diagnostic and performance validation processes, AFI KLM E&M can offer faster service and increased reliability, which is crucial for maintaining operational efficiency. The strategic advantage gained through these facilities supports the company's position in the competitive MRO market, potentially attracting more airline clients seeking reliable engine maintenance solutions.

What's Next?

AFI KLM E&M plans to continue investing in its Leap aftermarket network, including forming a Leap engine-focused leasing joint venture with AerCap. This initiative aims to support Premier MRO customers by building a pool of Leap-1A and 1B engines, further enhancing service offerings. The company is expected to leverage these advancements to strengthen its market presence and expand its customer base.

Beyond the Headlines

The development of advanced testing facilities reflects a broader trend in the aviation industry towards increased automation and precision in maintenance operations. This shift could lead to long-term improvements in aircraft reliability and safety, as well as reduced environmental impact through optimized engine performance.