What's Happening?

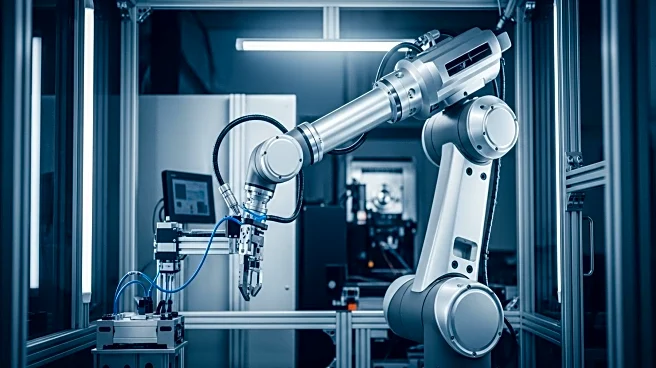

South Coast Robotics has developed a 'vanishing tray' system to address space constraints in a home-care products manufacturer's facility. This system uses pneumatic cylinders to drop empty trays through gravity feed to a lower conveyor, freeing up floor

space. The inverted robot configuration allows easy access for operators during maintenance and product changeovers across 30 SKUs. Strategic component placement, including IP67-rated valve manifolds and an actuator-mounted vision system, reduces control cabinet size and commissioning costs. The automation solution focuses on tray unloading stations, where small bottles are removed from trays and loaded into blister packaging.

Why It's Important?

The development of the vanishing tray system is significant for manufacturers facing space constraints, as it offers a practical solution to optimize floor space and improve operational efficiency. By automating the tray unloading process, manufacturers can reduce manual labor and increase throughput, leading to cost savings and enhanced productivity. The system's ability to accommodate rapid changeovers is particularly beneficial for manufacturers with diverse product lines, allowing them to maintain flexibility and responsiveness to market demands.

Beyond the Headlines

The implementation of such innovative robotics solutions highlights the growing trend towards automation in manufacturing. As companies seek to improve efficiency and reduce costs, the adoption of advanced robotics systems is likely to increase. This shift could lead to changes in workforce dynamics, with a greater emphasis on technical skills and robotics management. Additionally, the integration of robotics in manufacturing processes may drive further innovation in product design and packaging solutions.