What's Happening?

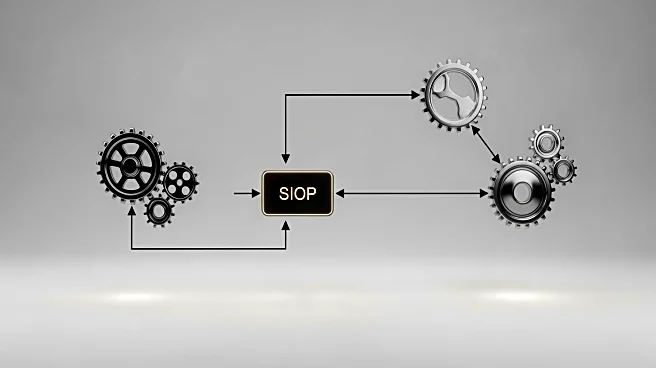

Sales, Inventory, and Operations Planning (SIOP) is a structured process that aligns sales forecasts, inventory levels, and operational capacity to balance supply and demand. This approach helps businesses

predict customer needs, maintain optimal stock levels, and ensure efficient operations. Effective SIOP planning can reduce inventory costs by 15-20% and improve customer satisfaction by 25%. The process involves data gathering, demand forecasting, supply planning, stakeholder meetings, and implementation.

Why It's Important?

SIOP is crucial for businesses aiming to optimize their supply chains, reduce costs, and enhance customer satisfaction. By aligning sales, inventory, and operations, companies can avoid overstocking or stockouts, leading to better resource management and financial performance. The process supports strategic decision-making and operational efficiency, providing a competitive edge in the market.

What's Next?

Businesses implementing SIOP may see improved operational metrics and financial outcomes. As more companies adopt this approach, it could lead to industry-wide improvements in supply chain management. Continuous refinement of SIOP processes, driven by data analytics and technology, may further enhance its effectiveness and adaptability to changing market conditions.