What's Happening?

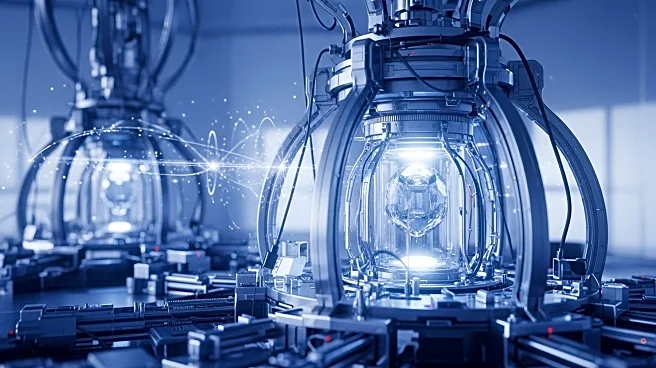

Recent research has demonstrated the effectiveness of cryogenic-temperature grain-to-grain epitaxial growth in improving the quality of ultrathin CoFe layers on MgFeO tunnel barriers for magnetic tunnel junctions

(MTJs). The study highlights that depositing CoFe at 100 K, as opposed to 300 K, suppresses island-like growth, resulting in a more uniform layer. This method enhances the magnetic properties and interfacial perpendicular magnetic anisotropy (PMA) of MTJs, which are crucial for applications in magnetic random-access memory (MRAM). The research also shows that the MgFeO barrier improves the wettability and uniformity of the CoFe layer, contributing to better performance in terms of magnetization and tunneling magnetoresistance (TMR) ratios.

Why It's Important?

The advancements in MTJ technology are significant for the development of high-performance MRAM, which is essential for next-generation computing and data storage solutions. The improved magnetic properties and reduced damping in ultrathin CoFe layers can lead to more efficient and reliable MRAM devices. This research could pave the way for more energy-efficient memory technologies, potentially reducing power consumption in electronic devices. The findings also highlight the importance of material science innovations in enhancing the capabilities of electronic components.

Beyond the Headlines

The use of cryogenic temperatures in material deposition could have broader implications for other areas of nanotechnology and materials science. This approach may lead to new methods for creating high-quality thin films with applications beyond electronics, such as in sensors and other advanced materials. The research underscores the potential for interdisciplinary collaboration between material scientists and engineers to develop innovative solutions for technological challenges.