What is the story about?

What's Happening?

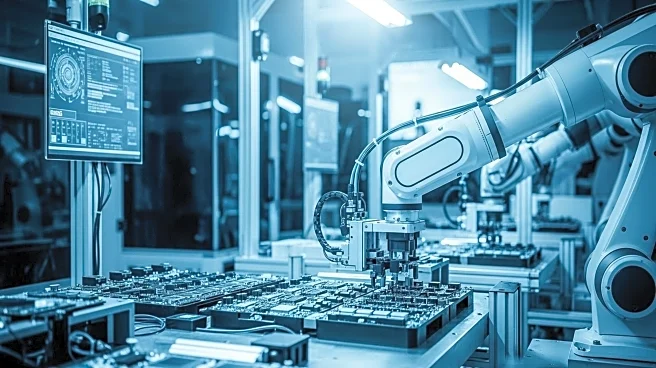

The integration of automation and artificial intelligence is reshaping the landscape of electronics manufacturing. Nine out of ten manufacturers have integrated AI into their operations, with the smart factory software market projected to reach $97 billion by 2028. This shift comes amid a persistent labor shortage, with an estimated 500,000 to 600,000 open positions. Automation and intelligent systems have become essential tools for survival and growth, enhancing precision, scalability, and operational efficiency while reducing human error and production delays.

Why It's Important?

The adoption of advanced technologies in electronics manufacturing is crucial for addressing labor shortages and improving efficiency. Automation and AI-driven systems offer significant advantages, including enhanced safety, improved consistency, and continuous operation. These technologies are transforming factories into dynamic ecosystems where human expertise and machine intelligence work in sync, driving the industry towards greater precision and environmental responsibility.

What's Next?

As these technologies continue to mature, their combined influence will redefine efficiency in electronics production. Manufacturers are likely to further integrate AI and automation to optimize operations and reduce costs. The industry will continue to evolve, with technology, design, and logistics working together towards a faster and cleaner future.

Beyond the Headlines

The integration of intelligent systems allows manufacturers to make decisions rooted in real-time data, predict challenges before they escalate, and achieve greater consistency across global operations. This transformation reflects a complete shift in how industries think, design, and deliver, pushing production closer to flawless precision and environmental responsibility.