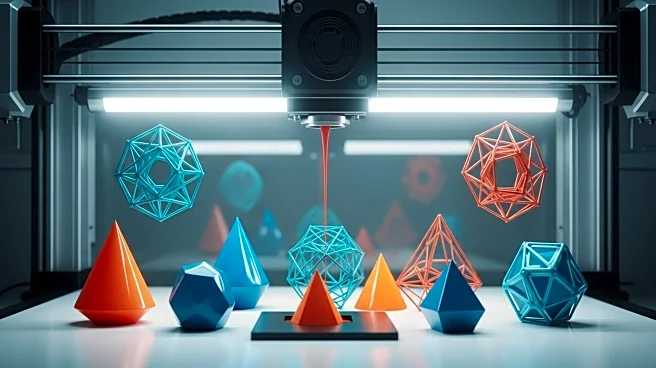

What's Happening?

Polyplastics Group has unveiled its DURAST Powder technology, which transforms high-performance resins into fine powders suitable for diverse manufacturing processes, including 3D printing and mass production. This technology successfully micronizes high-strength resins like liquid crystal polymer (LCP) and polyphenylene sulfide (PPS), overcoming challenges such as particle agglomeration and reduced flowability. The powders produced have particle sizes ranging from 20 to 100 micrometers, offering excellent flowability and mixing dispersibility. This advancement is expected to enhance the production of complex shapes and high-precision parts, and serve as a matrix resin for carbon fiber-reinforced thermoplastics.

Why It's Important?

The introduction of DURAST Powder technology by Polyplastics represents a significant advancement in the field of engineering plastics. By enabling the efficient powderization of high-performance resins, this technology opens new possibilities for manufacturing processes, particularly in additive manufacturing and 3D printing. This could lead to improved product quality and process stability, benefiting industries that rely on high-precision parts. Additionally, the technology's potential use in carbon fiber-reinforced thermoplastics could enhance material strength and durability, offering advantages in sectors such as automotive and aerospace.