What's Happening?

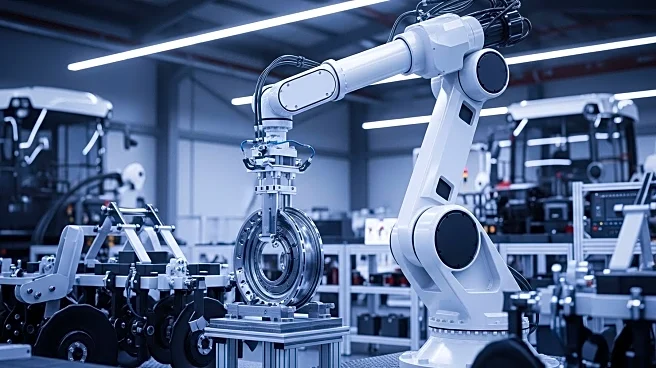

The agricultural equipment manufacturing industry is undergoing a significant transformation with the integration of robotic assembly systems. This shift is driven by the need for enhanced precision, cost containment, and compliance with global standards. Leading robotic automation integrators such as FANUC, ABB, KUKA, and Yaskawa Motoman are at the forefront, specializing in automating complex processes like welding, painting, and material handling. These integrators are incorporating AI, vision-based quality assurance, and Industrial IoT connectivity to improve efficiency and reliability. The adoption of robotic systems is becoming essential for manufacturers of tractors, harvesters, and irrigation systems, as they seek scalable automated production lines to meet the demands of modern agriculture.

Why It's Important?

The integration of robotic assembly systems in agricultural equipment manufacturing is crucial for maintaining global competitiveness and meeting rising standards. It allows manufacturers to enhance efficiency, reduce labor challenges, and ensure compliance with stricter regulations. This transformation supports the agricultural sector's move towards precision farming and sustainability, offering cost savings and improved production agility. As automation expands, there is a growing demand for a skilled workforce capable of managing both the ecological and technical aspects of agriculture. Educational programs that integrate farm, forest, and classroom experiences are essential for preparing the workforce needed to support advanced automation and sustainability goals.

What's Next?

As the industry moves towards 2025 and beyond, the adoption of collaborative robots (cobots) and the integration of digital twins and AI-driven maintenance are expected to increase. These technologies will reduce downtime and enhance equipment uptime, supporting predictive and prescriptive analytics. The expansion of semester schools and specialized university programs will produce a new, highly skilled workforce equipped to support advanced automation in farming technology. Manufacturers will continue to evaluate robotic integrators based on system scalability, ease of integration, and after-sales support, ensuring they choose the right partners to maintain competitiveness and meet future agricultural standards.

Beyond the Headlines

The rise of robotic assembly systems in agriculture highlights the ethical and cultural dimensions of automation. As machines take on more roles traditionally performed by humans, there is a need to address workforce displacement and ensure equitable access to new job opportunities. The integration of technology in agriculture also raises questions about data privacy and security, as IoT connectivity and AI-driven systems become more prevalent. Long-term shifts in agricultural practices may lead to changes in rural communities and the global food supply chain, emphasizing the importance of sustainable and responsible innovation.