What's Happening?

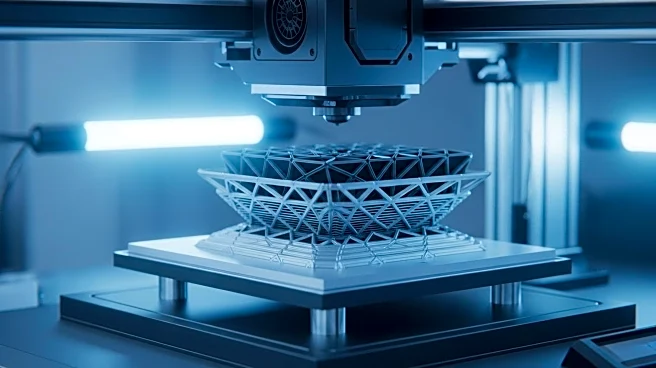

Researchers at the University of Michigan and the Air Force Research Laboratory have developed 3D-printed metamaterials designed to dampen mechanical vibrations. These structures, known as kagome tubes,

utilize complex geometries to passively isolate vibrations. The study, published in Physical Review Applied, highlights the potential of these materials in applications such as transportation and civil engineering. The research builds on decades of theoretical work, combining structural engineering, physics, and advanced fabrication technologies to create materials with unique mechanical properties.

Why It's Important?

The development of 3D-printed metamaterials for vibration isolation represents a significant advancement in material science and engineering. These materials could revolutionize industries that require vibration damping, such as automotive, aerospace, and construction. By leveraging complex geometries rather than chemical composition, researchers can create materials with unprecedented properties, potentially leading to more efficient and durable structures. This innovation could drive new standards in material testing and application, impacting how industries approach design and manufacturing.

Beyond the Headlines

The creation of these metamaterials raises questions about the trade-offs between vibration isolation and structural support. As researchers continue to explore these materials, they may uncover new behaviors and applications, necessitating the development of new testing standards and design processes. The study also highlights the intersection of historical physics concepts with modern fabrication technologies, suggesting a future where materials are engineered with precision from the ground up.