What's Happening?

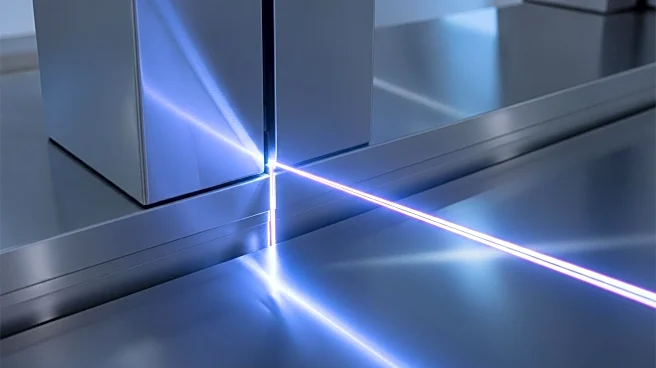

Recent advancements in laser technology have demonstrated a significant reduction in the corrosion of stainless steel, a material widely used in maritime infrastructure. The study, conducted using a Ti: Sapphire laser system, focused on various steel samples, including AISI 304 and 316, and titanium alloys. The laser treatment involved a strong-field laser filament interacting with the steel surface, resulting in improved anticorrosion performance. This process, which includes polishing and cleaning the samples, followed by laser scanning, has shown promising results in extending the lifespan of materials used in port terminals and marine oil and gas facilities. The research highlights the potential of laser surface passivation to enhance the durability of stainless steel, which is crucial for maintaining the integrity of maritime structures.

Why It's Important?

The reduction of corrosion in stainless steel through laser technology is a significant development for the maritime industry. Corrosion is a major challenge that affects the longevity and safety of maritime infrastructure, leading to costly repairs and replacements. By improving the corrosion resistance of stainless steel, this technology can potentially reduce maintenance costs and enhance the safety of maritime operations. The ability to extend the lifespan of materials used in critical infrastructure such as port terminals and marine facilities can have a positive impact on the economy, reducing the need for frequent replacements and ensuring uninterrupted operations. This advancement also aligns with efforts to improve sustainability in industrial practices by minimizing material waste and resource consumption.

What's Next?

Further research and development are expected to optimize the laser treatment process for broader applications in the maritime industry. Stakeholders, including maritime engineers and infrastructure developers, may explore the integration of this technology into existing maintenance protocols to enhance the durability of their assets. Additionally, regulatory bodies might consider updating standards to incorporate advanced corrosion resistance techniques, ensuring that new constructions benefit from these technological advancements. Collaboration between research institutions and industry players could accelerate the adoption of laser surface passivation, potentially leading to widespread improvements in maritime infrastructure resilience.

Beyond the Headlines

The ethical implications of adopting advanced laser technology in industrial applications include considerations of workforce displacement due to automation. As laser treatments become more prevalent, there may be a shift in the demand for skilled labor, necessitating retraining programs to equip workers with new skills. Furthermore, the environmental benefits of reduced material waste and resource consumption align with global sustainability goals, highlighting the importance of technological innovation in achieving eco-friendly industrial practices.