What's Happening?

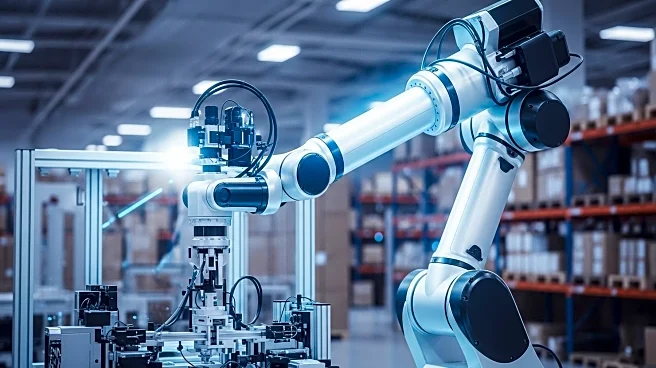

ABB has introduced new AI-powered functional modules designed to enhance automation in logistics and intralogistics operations. The Robotic Fashion Inductor and Robotic Parcel Inductor enable high-speed singulation and sorter induction for various items, including apparel and parcels. These modules can handle unknown and randomly arranged items in unstructured environments, achieving picking accuracy of over 99.5%. The AI system is capable of detecting and rejecting non-inducible items, offering a comprehensive solution for logistics automation.

Why It's Important?

The introduction of AI functional modules by ABB represents a significant advancement in logistics automation, potentially increasing efficiency and accuracy in handling diverse items. This technology can streamline operations in warehouses and distribution centers, reducing labor costs and improving throughput. As e-commerce continues to grow, the demand for efficient logistics solutions is increasing, making these AI modules crucial for businesses seeking to optimize their supply chain operations.

What's Next?

ABB's AI functional modules are likely to see widespread adoption in logistics and intralogistics sectors, with companies integrating these solutions to enhance operational efficiency. The ability to handle unstructured environments and achieve high accuracy rates may lead to further innovations in AI-driven logistics technologies. Businesses may explore additional applications of these modules in other areas of supply chain management.

Beyond the Headlines

The deployment of AI in logistics automation raises questions about the future of workforce roles in these sectors. While technology can improve efficiency, it also necessitates a shift in workforce skills and training. Companies may need to invest in reskilling programs to ensure employees can effectively work alongside advanced AI systems, balancing technological advancements with human expertise.