What's Happening?

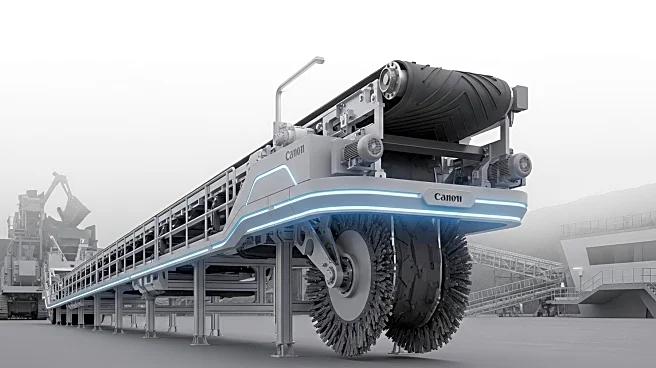

Flexco has unveiled its new Flextreme PXT Secondary Belt Cleaner Cushion, designed for heavy-duty mining applications. This breakthrough product aims to enhance the efficiency and durability of conveyor belt systems used in mining operations. The PXT cushion features a single-piece stainless steel body with a polyurethane dampener, offering superior durability and reducing the risk of delamination. It is 15% lighter than previous designs, improving safety during maintenance by reducing manual handling effort. The cushion is engineered to handle long shutdown cycles, high-speed belts, and increased tonnage applications.

Why It's Important?

The introduction of the Flextreme PXT cushion is significant for the mining industry, as it addresses the need for more reliable and efficient conveyor belt systems. Mining operations often face challenges with equipment durability and maintenance, which can impact productivity and safety. Flexco's innovative design offers a solution that enhances the longevity and performance of conveyor belts, potentially reducing downtime and maintenance costs. This development is likely to benefit mining companies by improving operational efficiency and safety, while also setting new standards for conveyor belt technology.

Beyond the Headlines

The Flextreme PXT cushion represents a shift towards more sustainable and efficient mining practices. By reducing the risk of equipment failure and improving safety, Flexco's product contributes to the broader goal of minimizing environmental impact and enhancing worker safety in mining operations. The adoption of such technologies may encourage other companies to invest in similar innovations, promoting a culture of continuous improvement and sustainability in the industry. Additionally, the cushion's compatibility with existing systems ensures a seamless transition for mining operations looking to upgrade their equipment.