What's Happening?

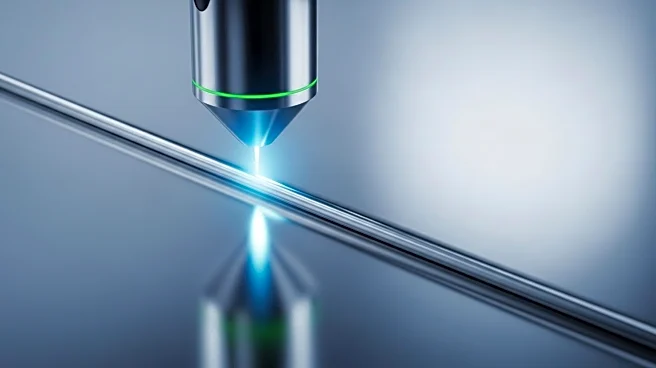

Recent advancements in laser technology have led to a significant reduction in the corrosion of stainless steel through a process known as strong-field laser surface passivation. This technique involves using a Ti: Sapphire laser system to produce a linearly polarized laser pulse train, which interacts with the steel surface to create a protective layer. The process has been tested on various steel types, including AISI 304, 316, 420, 201, 430, and 2205, as well as titanium alloy and pure aluminum samples. The laser treatment results in micro/nanostructured surfaces that exhibit enhanced resistance to corrosive environments, such as NaCl aqueous solutions. Electrochemical measurements, including electrochemical impedance spectroscopy and potentiodynamic polarization curves, confirm the improved anticorrosion performance of the treated samples. This development could have significant implications for industries reliant on stainless steel, offering a more durable and cost-effective solution to corrosion-related challenges.

Why It's Important?

The reduction of corrosion in stainless steel through laser surface passivation is crucial for industries such as construction, automotive, and aerospace, where material durability is paramount. Corrosion can lead to significant maintenance costs and safety risks, making this advancement a potential game-changer. By enhancing the longevity and reliability of stainless steel components, companies can reduce operational costs and improve product safety. Additionally, this technology could lead to more sustainable practices by minimizing the need for frequent replacements and repairs, thus reducing waste and resource consumption. The broader adoption of this technique could also stimulate innovation in material science, encouraging further research into laser-based treatments for other materials.

What's Next?

The next steps involve scaling the laser surface passivation process for industrial applications. Researchers and manufacturers will likely focus on optimizing the technique for different types of stainless steel and other metals, ensuring compatibility with existing manufacturing processes. There may also be efforts to integrate this technology into production lines, requiring collaboration between laser technology developers and steel manufacturers. As the process becomes more widely adopted, regulatory bodies might establish standards to ensure consistent quality and safety across industries. Additionally, further research could explore the environmental benefits of reduced corrosion, potentially influencing policy decisions related to industrial sustainability.

Beyond the Headlines

Beyond its immediate industrial applications, the laser surface passivation technique could have ethical and environmental implications. By reducing corrosion, this technology contributes to longer-lasting products, which can decrease the environmental impact associated with manufacturing and disposal. Ethically, it supports the development of safer products, reducing the risk of structural failures due to corrosion. The technique also highlights the importance of interdisciplinary collaboration in advancing material science, combining expertise in laser technology, chemistry, and engineering to achieve practical solutions.