What's Happening?

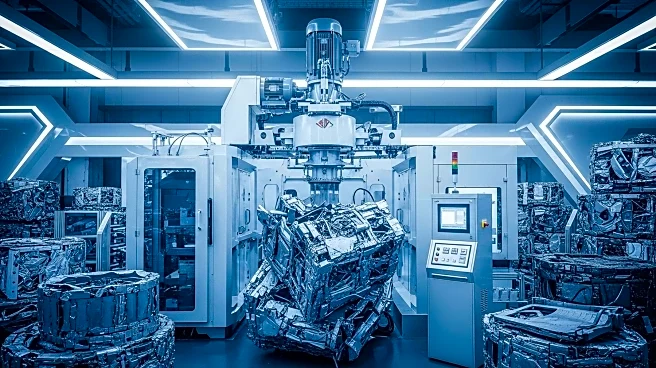

Researchers at the University of Leoben in Austria have developed a new method to recycle scrap metal from cars, potentially eliminating millions of tonnes of waste annually. Traditionally, scrap aluminum from vehicles has been recycled into low-grade cast alloys for combustion engine blocks. However, with the automotive industry's shift towards electric vehicles, this low-grade metal has no current application, risking the creation of large amounts of unusable scrap. The new process involves melting down all scrap aluminum from a car, including various alloys and impurities, to produce a brittle material. Reheating this material transforms it into a strong and moldable metal, suitable for manufacturing car components. This innovation could reduce carbon emissions by decreasing the need for virgin aluminum production.

Why It's Important?

The development of this recycling process is significant as it addresses the environmental challenges posed by the transition to electric vehicles. By utilizing scrap metal, the process could reduce the carbon footprint associated with aluminum production, benefiting the automotive industry and the environment. The ability to recycle scrap metal into high-grade aluminum alloys could lead to more sustainable manufacturing practices and reduce reliance on new raw materials. This advancement may also encourage the automotive sector to adopt greener technologies, aligning with global efforts to combat climate change.

What's Next?

The research team is in discussions with industry partners to scale the process for commercial use. However, challenges remain in ensuring the new alloy meets stringent automotive standards and in managing the variability of scrap metal compositions. Further testing and development are needed to prove the alloy's consistency and suitability for car body parts. If successful, this process could revolutionize the recycling industry and promote sustainable practices in vehicle manufacturing.