What's Happening?

Bioprocess 5.0 represents a new era in biomanufacturing, integrating advanced digital technologies, automation, and sustainability principles to streamline the production of biological products such as pharmaceuticals, vaccines, and enzymes. This approach utilizes artificial intelligence (AI) tools to optimize and control bioprocess parameters in real-time, improving quality and standardization. Digital twins, virtual replicas that simulate processes, are employed to test scenarios, minimizing risks and increasing process consistency. The initiative also emphasizes sustainability, with companies like MilliporeSigma operating with a significant percentage of renewable electricity and aiming to increase this further. Human-centric automation is a key aspect, where digital tools enhance manufacturing capabilities without replacing human decision-making.

Why It's Important?

The integration of AI and sustainable practices in bioprocessing is crucial for the pharmaceutical industry, as it promises to enhance efficiency, reduce errors, and accelerate the speed-to-clinic for new therapies. This approach can significantly lower production costs and improve the scalability of personalized therapies, such as CAR T cell therapies for larger patient populations. The focus on sustainability aligns with global efforts to reduce environmental impact, making bioprocessing more eco-friendly. The advancements in Bioprocess 5.0 could lead to broader accessibility of complex biologics, benefiting patients with rare diseases and unmet medical needs.

What's Next?

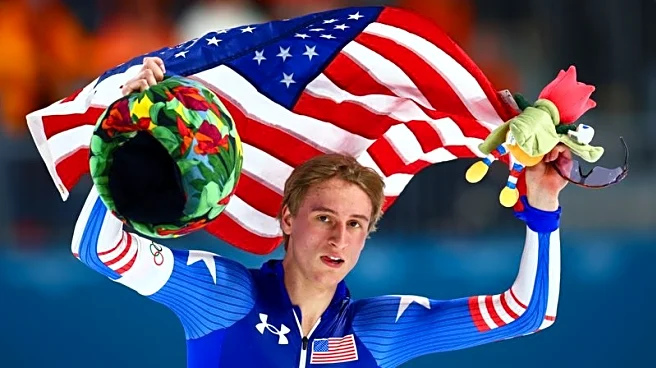

The bioprocessing industry is expected to continue evolving with the adoption of Bioprocess 5.0 principles. Companies are likely to increase their use of renewable energy and further develop eco-friendly products. The partnership between Cytiva and Cellular Origins aims to scale the production of cell and gene therapies, potentially expanding their reach to larger populations. Regulatory approaches may adapt to facilitate the transition from N-of-1 therapies to N-of-many, enhancing commercial viability for rare disease treatments. The industry will focus on improving sustainability metrics and defining the value proposition for human roles in biomanufacturing.

Beyond the Headlines

Bioprocess 5.0 not only enhances manufacturing efficiency but also raises ethical considerations regarding the balance between human and machine roles in production. The emphasis on human-centric automation suggests a shift towards collaborative work environments where digital tools support rather than replace human expertise. This approach may redefine job roles and require new skill sets in the biomanufacturing workforce. Additionally, the focus on sustainability reflects a broader cultural shift towards environmentally responsible practices in industry.