What is the story about?

What's Happening?

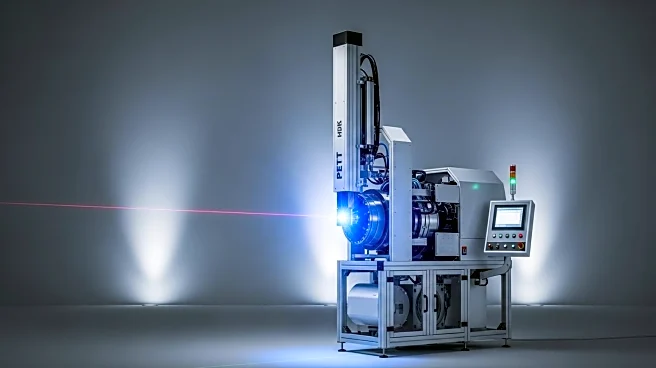

Sidel has introduced a groundbreaking laser-powered solution for PET bottle production, marking a significant advancement in the beverage industry. This new technology, showcased at the drinktec event in Munich, aims to enhance efficiency, quality, and sustainability in production processes. Unlike traditional halogen heating methods, the laser-powered ovens offer immediate readiness, eliminating downtime associated with heating and cooling periods. The precision of laser technology allows for better control over material thickness, facilitating lightweighting opportunities and increased use of recycled PET (rPET). This innovation is expected to set new standards for line efficiency and adaptability to changing production demands.

Why It's Important?

The introduction of laser-powered PET blowing technology by Sidel is poised to transform the beverage industry by significantly improving production efficiency and sustainability. As producers face increasing pressure to reduce costs and enhance environmental responsibility, this technology offers a solution that addresses these challenges. The ability to precisely control material thickness and reduce sensitivity to environmental conditions can lead to more sustainable packaging options and lower production costs. This advancement not only benefits manufacturers but also aligns with broader industry trends towards sustainability and resource efficiency.

What's Next?

With the laser-powered technology already operational in a European production facility, Sidel is likely to expand its implementation across more sites globally. As the industry adapts to this new technology, other manufacturers may follow suit, potentially leading to widespread adoption of laser-powered solutions. Stakeholders in the beverage industry, including producers and environmental advocates, will be closely monitoring the impact of this technology on production practices and sustainability metrics. Future developments may include further enhancements to the technology, increasing its applicability to other types of packaging and industries.

Beyond the Headlines

The shift from halogen to laser technology in PET bottle production could have broader implications for industrial manufacturing processes. The precision and efficiency offered by laser technology may inspire similar innovations in other sectors, promoting a move towards more sustainable and cost-effective production methods. Additionally, the increased use of rPET facilitated by this technology supports global efforts to reduce plastic waste and promote circular economy practices.