What's Happening?

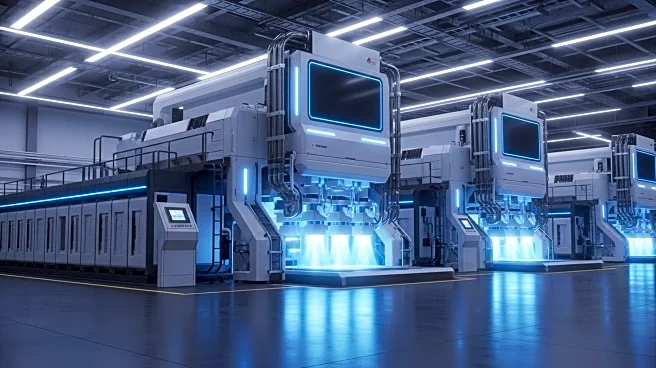

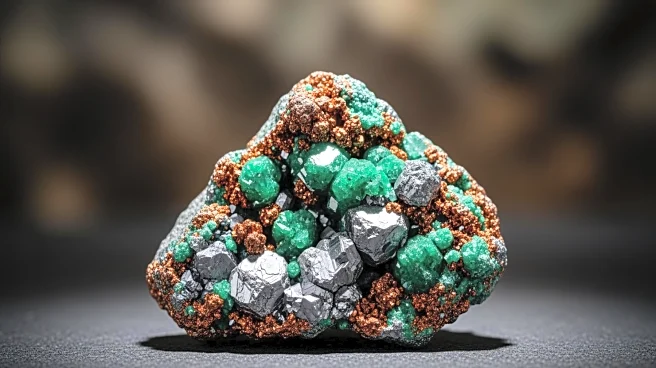

Researchers at the University of Minnesota Twin Cities have pioneered a novel method for producing iron, a key component in steel manufacturing, using hydrogen gas plasma. This innovative approach allows for the observation of chemical reactions and iron formation at the nanometer scale, a first in the field. The study, published in Nature Communications, highlights the potential of this method to revolutionize the iron and steel industry by enhancing energy efficiency and reducing costs. Traditional steel production methods are significant contributors to global carbon dioxide emissions, accounting for about 7% of the total. The new technique eliminates CO2 emissions by using hydrogen plasma to strip oxygen from iron ore, producing pure iron and water vapor. This process can be conducted at room temperature, making it more efficient and environmentally friendly. The research team collaborated with Hummingbird Scientific to develop a specialized holder for transmission electron microscopes, enabling the detailed observation of plasma-material interactions.

Why It's Important?

The development of this hydrogen plasma method for iron production could have significant implications for the U.S. manufacturing industry and global efforts to reduce carbon emissions. By potentially lowering the energy consumption and environmental impact of steel production, this innovation aligns with broader sustainability goals and could lead to cost savings for manufacturers. The ability to produce steel without the traditional reliance on coke, a type of coal, represents a major shift towards cleaner industrial processes. This advancement not only supports environmental objectives but also positions the U.S. as a leader in sustainable manufacturing technologies. Industries that rely heavily on steel, such as construction and automotive, could benefit from reduced material costs and a smaller carbon footprint.

What's Next?

The next steps for this research include scaling the hydrogen plasma method for industrial applications and further refining the process to enhance its efficiency and cost-effectiveness. Stakeholders in the steel industry, environmental groups, and policymakers may closely monitor these developments, as they could influence future regulations and industry standards. The University of Minnesota team may also explore partnerships with steel manufacturers to pilot the technology in real-world settings. As the method gains traction, it could prompt a reevaluation of current steel production practices and encourage investment in cleaner technologies.

Beyond the Headlines

This breakthrough in steel production technology could have broader implications for other industries that rely on high-temperature processes. The ability to conduct reactions at room temperature using plasma could inspire similar innovations in fields such as chemical manufacturing and energy production. Additionally, the environmental benefits of reducing carbon emissions from steel production could contribute to global climate change mitigation efforts. The research also underscores the importance of interdisciplinary collaboration, as demonstrated by the partnership between the University of Minnesota and Hummingbird Scientific, in achieving technological advancements.