What's Happening?

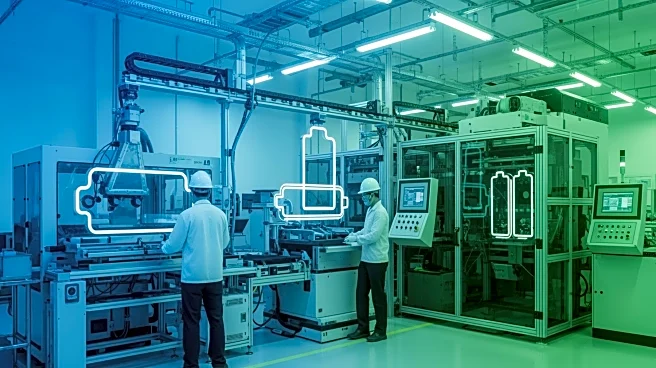

The recycling of end-of-life lithium-ion batteries (LIBs) presents a complex array of technical, economic, environmental, and regulatory challenges. These batteries, which include various chemistries such as nickel, manganese, cobalt, lithium iron phosphate,

and lithium cobalt oxide, are not designed for easy disassembly and recycling. The architecture of battery packs, particularly those used in electric vehicles, complicates the recycling process due to their robust design intended to maximize energy density and structural integrity. This results in labor-intensive and potentially hazardous disassembly processes. The recycling process involves collection, disassembly, and material recovery, with disassembly being the most critical bottleneck due to safety hazards and economic inefficiencies. Additionally, the diversification of next-generation battery chemistries, such as solid-state and lithium-sulfur batteries, introduces further complexity, requiring specific recycling routes for different materials.

Why It's Important?

The challenges in recycling lithium-ion batteries have significant implications for the sustainability of battery-based technologies and the broader electromobility and renewable energy sectors. Effective recycling is crucial for recovering critical materials like lithium, cobalt, and nickel, which are essential for future battery production and supply chain resilience. The inability to efficiently recycle these materials threatens to exacerbate resource scarcity and increase dependence on primary extraction, undermining the environmental and economic benefits of electric vehicles and clean energy technologies. Moreover, the fragmented regulatory landscape and economic constraints hinder the development of a circular battery economy, impacting the long-term viability of these technologies.

What's Next?

Addressing the bottlenecks in lithium-ion battery recycling requires advances in recycling technologies capable of handling mixed chemistries and evolving battery designs. There is a need for robust policy interventions to harmonize end-of-life management standards, incentivize circular practices, and ensure traceability across the battery value chain. Establishing regionally distributed recycling facilities near collection centers and fostering international collaboration can improve the resilience and equity of global battery supply chains. Without systemic reform and coordinated innovation, the goal of closing the materials loop remains largely aspirational.

Beyond the Headlines

The challenges in lithium-ion battery recycling highlight the need for early community engagement and transparent governance when siting recycling facilities. Experiences from informal e-waste recycling in developing countries show that transitioning informal workers into formalized recycling systems requires substantial investment in reskilling programs and social safety nets. Without these measures, marginalized labor forces risk exclusion from the value chain, undermining the principles of a just transition. The fragmented recovery landscape not only undermines the sustainability narrative of battery technologies but also threatens the long-term viability of electromobility and renewable energy systems.