What's Happening?

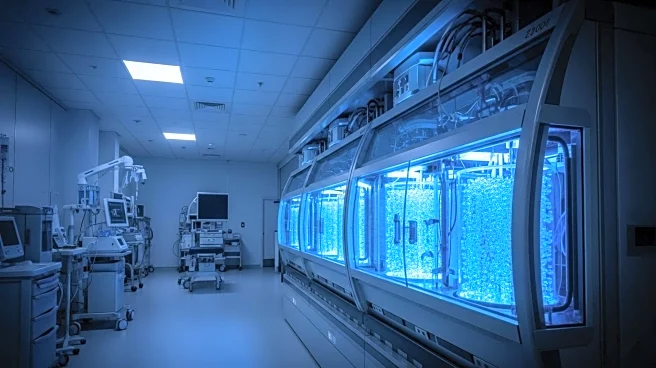

CTMC, a joint venture between Resilience and MD Anderson Cancer Center, is advancing the integration of biomanufacturing with clinical centers to improve the production of autologous cell therapies. This approach involves embedding manufacturing processes within major medical centers, allowing for streamlined production and faster delivery of therapies to patients. Jason Bock, CEO of CTMC, highlights the importance of connecting industrial-grade manufacturing directly to clinical centers, which facilitates efficient technology use and accelerates the transition from research to clinical application. CTMC's collaboration with Syenex to incorporate viral vector technology aims to enhance gene delivery and manufacturing scalability, ensuring high-quality standards for therapeutics produced for academic center patients.

Why It's Important?

The integration of advanced biomanufacturing with clinical centers represents a significant shift in the production of cell therapies, potentially reducing costs and increasing efficiency. By streamlining processes and coordinating logistics, CTMC aims to reduce labor costs and facility expenses while increasing throughput. This model not only accelerates the delivery of therapies but also ensures that manufacturing standards meet commercial-level quality. The approach could lead to faster clinical trials and regulatory approvals, benefiting patients by providing quicker access to innovative treatments. The collaboration between CTMC and Syenex further enhances the scalability and quality of gene delivery, which is crucial for the development of effective cell therapies.

What's Next?

CTMC's model of integrating biomanufacturing with clinical centers is attracting interest, although it is not yet a widespread trend. The company plans to continue optimizing interactions and processes to reach value inflection points sooner. As the integration model proves successful, it may encourage other biopharmaceutical companies to adopt similar strategies, potentially transforming the landscape of cell therapy production. Future collaborations and technological advancements could further enhance the efficiency and scalability of manufacturing processes, leading to broader adoption and improved patient outcomes.

Beyond the Headlines

The integration of biomanufacturing with clinical centers raises important ethical and logistical considerations. Ensuring that manufacturing processes adhere to rigorous quality standards while being embedded within clinical settings requires careful coordination and oversight. Additionally, the model challenges traditional manufacturing paradigms, prompting discussions about the balance between academic research and commercial production. As this approach gains traction, it may influence regulatory frameworks and industry standards, shaping the future of cell therapy development.