What's Happening?

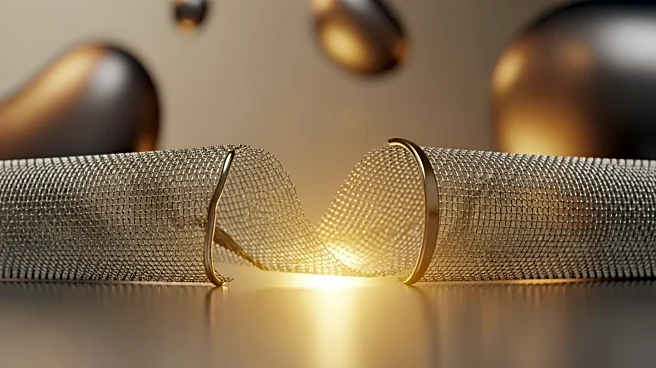

Researchers at Northwestern Polytechnical University have developed a new type of self-expanding stent that utilizes body heat and moisture to unfurl within the body. This innovation, detailed in the Chinese

Journal of Polymer Science, involves a dual stimuli shape memory polymer that expands at body temperature and in physiological fluid. The stent is created using DLP-based 4D printing, allowing for customizable vascular implants that can recover their programmed shape with significant force while remaining soft enough to match vessel tissue. The material's nanoscale architecture involves amphiphilic PF127 DA molecules that self-assemble into micelles, which then lock into a crosslinked network during polymerization. This results in a strong yet pliable implant that can be compressed for delivery and then triggered to expand when exposed to body temperature and fluid.

Why It's Important?

The development of these self-expanding stents represents a significant advancement in minimally invasive vascular care. By eliminating the need for external heat, light, or mechanical force to activate the stent, the procedure becomes less invasive and potentially safer for patients. The ability to customize the geometry of the stent for each patient through 4D printing offers a path toward personalized vascular therapeutics, which could improve patient outcomes and expand access to care. Additionally, the material's low cytotoxicity and good adhesion make it biologically friendly, an important factor for implants that must remain inside the body under constant motion and stress.

What's Next?

Future research will focus on exploring biodegradable variants of the material and assessing in vivo performance. The concept of using body heat to activate implants could extend beyond stents to other applications requiring shape change inside the body, such as tissue scaffolds and drug-releasing devices. The potential for these materials to store and release mechanical energy precisely under physiological conditions may lead to new types of implants that can expand, bend, or anchor in situ, further simplifying medical procedures and enhancing patient care.

Beyond the Headlines

This innovation highlights the potential for advanced materials to transform medical procedures by reducing the invasiveness and complexity of implant deployment. The use of body heat as a natural trigger for implant activation aligns with a broader trend in medical technology towards more patient-friendly solutions that minimize the need for external interventions. As research progresses, these materials could pave the way for a new era of soft implants that offer both deployment convenience and compatibility with the body's natural environment.