What's Happening?

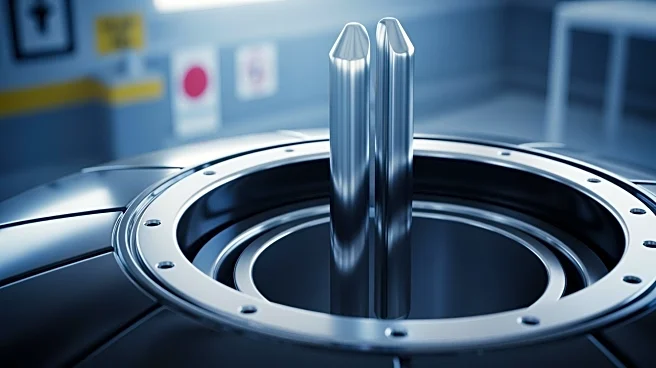

Motion Industries, Inc., a distributor specializing in replacement parts for maintenance and repair, has unveiled the Motion Lube Caddy. This innovative product is designed to streamline the process of changing lubrication oil in enclosed machinery, hydraulic systems, and mobile or agricultural equipment. The caddy features mobile lubrication reservoirs, eliminating the need for forklifts to transport lubrication tanks. It is equipped with an air-operated pump capable of 500psi back pressure and an automatic shutoff, operable in manual, automatic, and kidney loop modes. The dual reservoir system offers 40- and 75-gallon capacities for used and new oil, with a 150-gallon hoistable option, ensuring sanitary oil changes. Quick disconnects on all external hose connections enhance its functionality. Scott Smith, Motion Repair & Services West Division Manager, highlighted the caddy's compact design and mobility, which allow maintenance teams to efficiently service equipment without the hassle of trailing hoses or spills.

Why It's Important?

The introduction of the Motion Lube Caddy represents a significant advancement in the maintenance and repair industry, particularly for manufacturers who regularly change lubrication oil in gearboxes and hydraulic systems. By providing a mobile and efficient solution, the caddy reduces downtime and labor costs associated with traditional lubrication methods. This innovation is likely to benefit industries reliant on heavy machinery, such as manufacturing and agriculture, by enhancing operational efficiency and reducing the risk of oil spills and contamination. The customizable nature of the caddy also allows it to be tailored to specific industry needs, potentially broadening its application and appeal.

What's Next?

Motion Industries plans to offer the Motion Lube Caddy in both standard and customizable models, catering to a wide range of industrial applications. As the product gains traction, it may prompt other companies in the maintenance and repair sector to innovate similar solutions, potentially leading to a shift in industry standards for machinery lubrication. Stakeholders in manufacturing and agriculture may closely monitor the caddy's performance and consider integrating it into their maintenance protocols to enhance efficiency and reduce operational costs.