What's Happening?

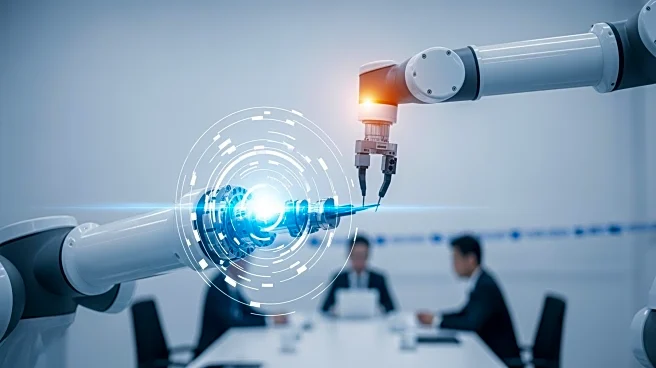

GrayMatter Robotics has inaugurated a new 100,000-square-foot headquarters and innovation center in Carson, California. This facility is designed to be the most advanced interactive robotics experience

center for AI-powered manufacturing automation in the U.S. The company aims to bring advanced manufacturing back to American soil, leveraging its proximity to aerospace and marine manufacturing clusters and access to skilled workforce. GrayMatter Robotics provides AI-driven robotic cells to tackle complex surface-finishing tasks, such as sanding and polishing, which are traditionally labor-intensive. The new facility addresses challenges in automating high-mix production environments, where product variability has hindered automation efforts. GrayMatter's systems promise efficiency by autonomously programming themselves and adapting to part variations without human intervention, operating faster than manual processes.

Why It's Important?

The opening of GrayMatter Robotics' innovation center marks a significant step in revitalizing U.S. manufacturing through advanced automation. By addressing the challenges of high-mix production environments, the company is helping manufacturers reduce reliance on manual labor, which is increasingly difficult to staff. This development could lead to increased productivity and competitiveness for U.S. manufacturers, potentially reversing decades of manufacturing decline. The facility is expected to create over 100 jobs, contributing to the local economy and supporting workforce development initiatives. GrayMatter's approach to 'physical AI' represents a shift in how products are made, with implications for safety, efficiency, and continuous learning in manufacturing processes.

What's Next?

GrayMatter Robotics plans to expand its physical AI applications beyond surface finishing, increasing its manufacturing capacity and customer base. The company aims to use the facility for workforce development, hosting student tours and industry conferences to advance intelligent manufacturing. Strategic partnerships with companies like FANUC and 3M will support the integration of advanced robotics and materials science into GrayMatter's systems. As the company scales, it could add hundreds of skilled positions, further boosting the local economy and demonstrating the viability of advanced manufacturing in Southern California.

Beyond the Headlines

GrayMatter Robotics' focus on 'physical AI' highlights a broader trend in AI development, moving beyond digital applications to real-world manufacturing challenges. This approach requires AI systems to interact with and manipulate the physical world, accounting for variability in materials and part dimensions. The company's success could influence other sectors to adopt similar technologies, potentially transforming industries that rely on complex, variable production processes.