What's Happening?

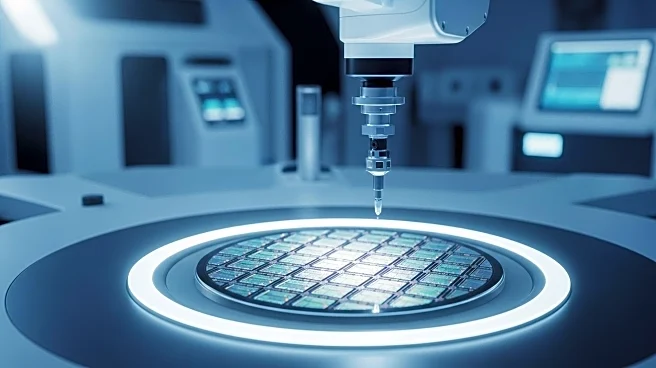

Advantest Corporation has introduced its next-generation CD-SEM E3660, designed for the dimensional metrology of photomasks and EUV masks in semiconductor manufacturing. The E3660 offers over a 20% improvement in CD reproducibility compared to its predecessor, enabling process engineers to meet stringent requirements for mask manufacturing at the 2nm node and beyond. The system supports curvilinear mask patterns, expected to be widely deployed by 2027 with High Numerical Aperture EUV lithography. Advantest collaborated with imec to validate the correlation of CD-SEM results, enhancing metrology reliability.

Why It's Important?

The launch of the E3660 is a significant advancement in semiconductor manufacturing, addressing the industry's need for precise metrology solutions. As semiconductor devices become more complex, the demand for accurate mask measurements increases. The E3660's capabilities in handling curvilinear patterns and high-throughput measurement are crucial for maintaining design-to-mask fidelity. This development supports the industry's transition towards more intricate geometries and higher layer counts, ensuring the reliability and efficiency of semiconductor production processes.

What's Next?

Advantest plans to deploy the E3660 at Merchant Mask Shops and Captive Mask Shops, establishing it as a core tool for advanced mask development and production qualification. The system's unique measurement functions for curvilinear patterns will be essential as the industry moves towards large-scale deployment of High Numerical Aperture EUV lithography. Advantest's collaboration with imec may lead to further innovations in metrology techniques, supporting the industry's ongoing evolution.