What's Happening?

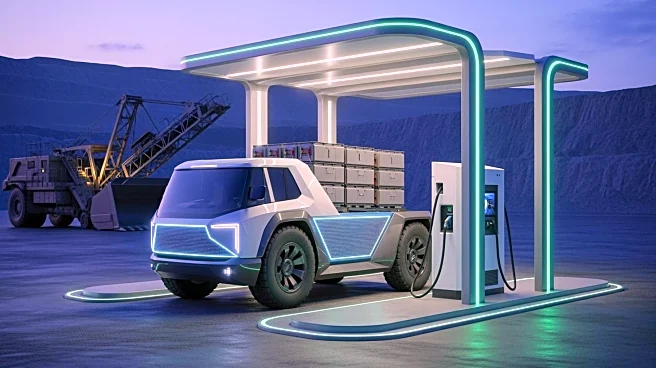

Rio Tinto has initiated a trial of battery-swap electric haul trucks at the Oyu Tolgoi copper mine in Mongolia. This trial, conducted in partnership with China's State Power Investment Corporation (SPIC)

Qiyuan, involves the deployment of eight 91-ton Tonly trucks and 13 batteries, each with an 800 kWh capacity. The initiative aims to test cost-effective technologies to reduce emissions from Rio Tinto's haulage fleet, a significant contributor to its carbon footprint. The battery-swap technology allows for a depleted battery to be replaced in under seven minutes, enhancing fleet efficiency by minimizing downtime. The trial will continue until the end of 2026, providing Rio Tinto with valuable insights into the operation and maintenance of a battery-electric haulage system.

Why It's Important?

This trial represents a significant step in Rio Tinto's efforts to decarbonize its operations and reduce its environmental impact. By adopting battery-swap technology, the company aims to improve the efficiency of its haulage fleet while cutting emissions. This move aligns with global trends towards sustainable mining practices and could set a precedent for other mining companies to follow. The success of this trial could lead to broader adoption of battery-electric technology across Rio Tinto's fleet, potentially influencing industry standards and contributing to global emission reduction goals.

What's Next?

The trial will continue through 2026, during which Rio Tinto will gather data and operational insights. These findings will inform the company's decision on whether to expand the use of battery-swap technology across its entire fleet of 700 haul trucks. The outcome of this trial could also influence Rio Tinto's future partnerships and investments in low-carbon technologies, as well as its overall strategy for achieving sustainability targets.