What's Happening?

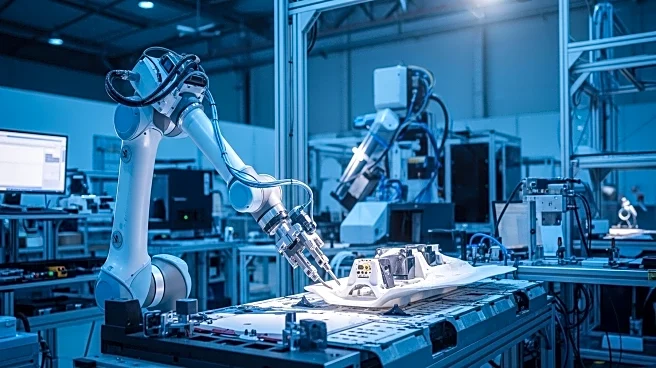

CT UAV has introduced a self-evolving composite molding plant, enhancing its capabilities in UAV manufacturing. The facility, located in Ho Chi Minh City, Vietnam, focuses on advanced composite materials and automation processes. It integrates next-generation materials, digital simulation, and quality control systems to produce UAV components with high precision. The plant aims to revolutionize UAV production by utilizing cutting-edge technologies such as AI-driven decision-making and digital twin systems.

Why It's Important?

The development of this advanced manufacturing plant positions CT UAV as a leader in the UAV industry, potentially impacting global markets. The use of innovative materials and technologies could lead to more efficient and cost-effective UAV production, benefiting industries reliant on UAV technology. This advancement may also drive competition and innovation in the aerospace sector, influencing future manufacturing standards.

What's Next?

CT UAV plans to continue expanding its technological capabilities, focusing on automation and AI integration. The company aims to enhance its production processes and explore new applications for its UAV technology. Stakeholders in the aerospace industry should watch for further developments and potential collaborations with CT UAV.

Beyond the Headlines

The plant's emphasis on sustainability and advanced materials reflects a broader trend towards environmentally friendly manufacturing practices. This shift could influence industry standards and encourage other companies to adopt similar technologies.