What's Happening?

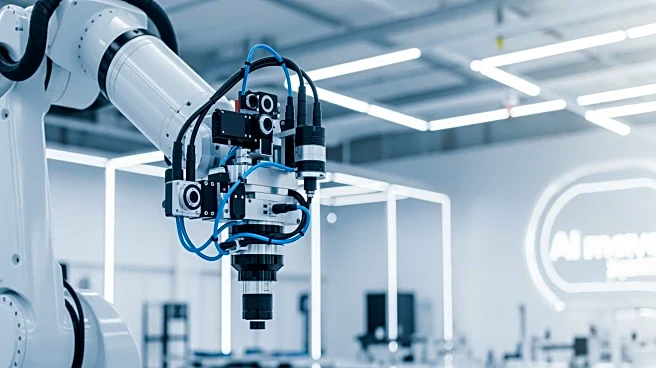

AI is revolutionizing predictive maintenance in manufacturing by utilizing machine learning to detect equipment failures before they occur. This approach combines data from Industrial Internet of Things

(IIoT) sensors with AI/ML analytics to proactively identify and resolve potential asset problems, minimizing downtime and reducing maintenance costs. The technology allows for the detection of non-standard problems and provides adaptive learning capabilities, making predictive maintenance practices more valuable.

Why It's Important?

The integration of AI in predictive maintenance is significant for the manufacturing industry as it enhances operational efficiency and reduces costs associated with equipment downtime. By improving the accuracy of diagnostics and enabling proactive maintenance, AI helps manufacturers maintain continuous production and avoid costly disruptions. This advancement supports the industry's shift towards more automated and intelligent systems, potentially leading to increased competitiveness and innovation in manufacturing processes.

What's Next?

As AI continues to evolve, its application in predictive maintenance is expected to expand, potentially leading to more sophisticated and comprehensive maintenance strategies. Manufacturers may increasingly adopt AI-driven solutions to optimize their operations, and the technology could be integrated into other areas of industrial automation, further enhancing productivity and efficiency.

Beyond the Headlines

The use of AI in predictive maintenance also raises considerations regarding data privacy and security, as the technology relies on extensive data collection and analysis. Manufacturers will need to address these concerns to ensure the safe and ethical use of AI in their operations.