What is the story about?

What's Happening?

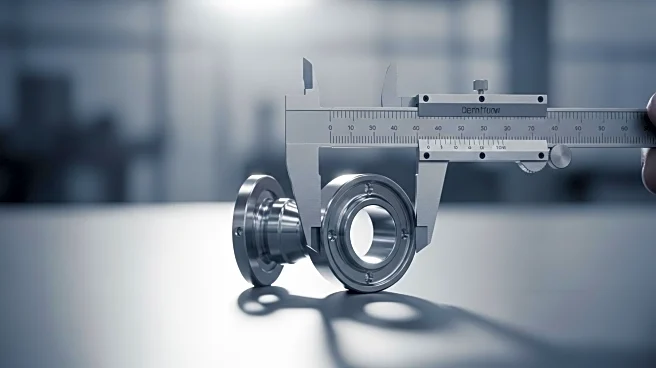

Six Sigma, a data-driven methodology for process improvement, is being utilized in manufacturing to enhance quality control and reduce defects. Originating at Motorola in the 1980s, Six Sigma focuses on minimizing variability and achieving high consistency in production. Manufacturers apply statistical analysis to sample testing, allowing them to ensure quality without exhaustive inspections. This approach is particularly prevalent in the automotive industry, where it helps design processes that produce reliable products from the start, reducing waste and improving efficiency.

Why It's Important?

The application of Six Sigma in manufacturing represents a significant advancement in quality control, offering a structured approach to achieving high standards. By reducing defects and variability, manufacturers can improve product reliability and customer satisfaction, impacting industries such as automotive and electronics. The methodology supports continuous improvement, driving innovation and competitiveness in the manufacturing sector. However, the pursuit of Six Sigma may not be necessary for all industries, as the cost of achieving it may outweigh the benefits in low-risk or low-cost sectors.

Beyond the Headlines

The integration of Six Sigma with AI tools in manufacturing highlights the potential for enhanced data analysis and process optimization. As AI becomes more prevalent, manufacturers can leverage its capabilities to further improve quality control and efficiency. This combination may lead to shifts in workforce dynamics, requiring new skills and training for employees. Additionally, the cultural impact of Six Sigma as a mindset emphasizes the importance of leadership in championing quality and fostering a culture of continuous improvement.