What's Happening?

Researchers at the Massachusetts Institute of Technology (MIT) have unveiled a groundbreaking 'speech-to-reality' system that allows users to create physical objects, such as furniture, through simple

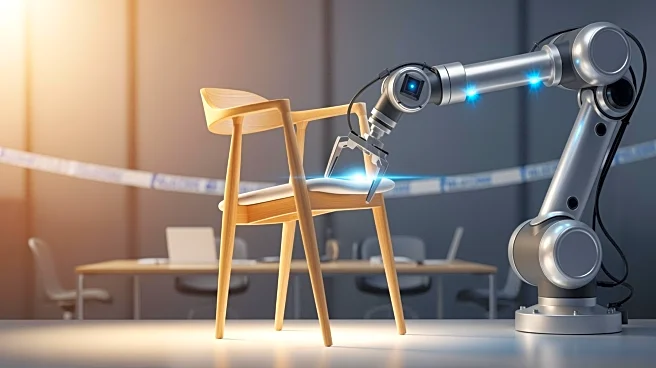

spoken commands. This innovative system integrates natural language processing, 3D generative AI, and robotic assembly to transform verbal requests into tangible items within minutes. The system employs a robotic arm that interprets spoken instructions to construct objects from modular components. The project, led by MIT graduate student Alexander Htet Kyaw, aims to make design and manufacturing more accessible to individuals without expertise in 3D modeling or robotic programming. The system has successfully created various items, including stools, shelves, and decorative objects, demonstrating its potential to revolutionize the way physical objects are produced.

Why It's Important?

This development represents a significant advancement in the field of automated manufacturing and design, potentially democratizing access to custom-made furniture and other objects. By reducing the time and expertise required to produce physical items, the system could disrupt traditional manufacturing processes and supply chains. It offers a sustainable approach by allowing objects to be disassembled and reassembled into new forms, minimizing waste. The technology could benefit industries ranging from interior design to construction, providing a rapid and flexible solution for creating customized products. Additionally, it highlights the growing intersection of artificial intelligence and robotics in practical applications, paving the way for further innovations in automated production.

What's Next?

The MIT team plans to enhance the system's capabilities by improving the weight-bearing capacity of the furniture and exploring more robust connection methods for the modular components. Future developments may include incorporating gesture recognition and augmented reality to further streamline the interaction between humans and robots. The team is also working on adapting the system for use with small, distributed mobile robots, which could expand its application to larger-scale structures. These advancements could lead to broader adoption of the technology across various sectors, potentially transforming how physical objects are designed and manufactured.