What is the story about?

What's Happening?

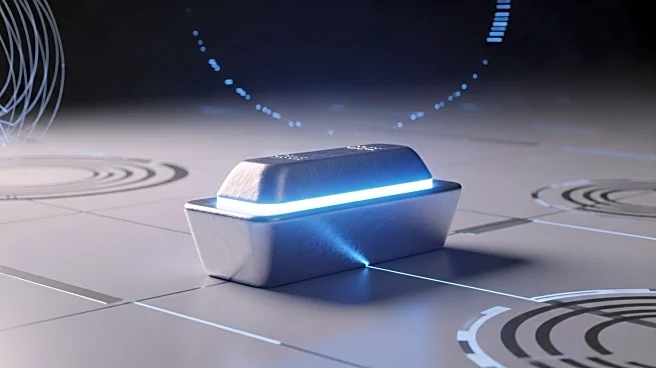

A Swedish company, in partnership with GE Vernova, has developed a new form of steel with near-zero carbon emissions, produced using hydrogen-reduced iron and renewable energy sources. This innovation aligns with the International Energy Agency's decarbonization goals and represents a significant milestone in sustainable energy efforts. The steel, manufactured in Montpelier, Iowa, utilizes recycled scrap, fossil-free electricity, biocoal, and renewable natural gas, significantly reducing its carbon footprint. The collaboration exemplifies the potential of industry-wide sustainability efforts and marks a shift towards environmentally conscious manufacturing.

Why It's Important?

The development of near-zero CO2e emission steel is a major advancement in reducing the carbon footprint of the steel industry, traditionally a significant contributor to global emissions. This innovation supports global decarbonization goals and sets a precedent for other manufacturers. The partnership with GE Vernova, a leader in wind energy, highlights the practical application of this steel in sustainable energy solutions, such as onshore wind towers. This collaboration demonstrates the potential for industry leaders to drive significant change through innovation and commitment to sustainability.

What's Next?

The challenge lies in scaling these innovations across the industry, requiring substantial investment and a shift in traditional production methods. The success of this initiative could inspire other companies to explore similar innovations, further accelerating the transition to a low-carbon economy. As the world moves towards a more sustainable energy economy, the role of innovative materials like SSAB Zero steel will become increasingly important. The focus will be on expanding these technologies to other sectors and regions, ensuring the benefits of reduced emissions are realized globally.