Light Over Electronics

Conventional electronic sensors often falter when exposed to intense heat or disruptive electromagnetic fields, leading to equipment failures and costly

power outages. A groundbreaking innovation from researchers at Shanghai University has introduced an all-fiber microphone, constructed solely from silica glass, designed to overcome these limitations. This hair-thin device operates by sensing vibrations through light, making it impervious to electromagnetic interference and capable of functioning reliably in environments reaching a staggering 1000°C. Its primary application involves integration into high-voltage transformers, where it can meticulously listen for subtle internal electrical sparks, providing crucial early warnings of developing problems before they escalate into cascading failures. This advancement promises a significant leap in predictive maintenance and the overall safety of critical infrastructure.

Ultrasound Detection

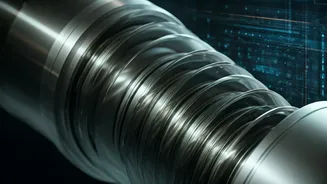

This remarkable fiber-optic microphone is engineered to detect a vast spectrum of sounds, specifically focusing on ultrasound frequencies ranging from 40 kHz up to an impressive 1.6 MHz, far exceeding the capabilities of human hearing. Unlike traditional microphones that require bulky external casings, the entire sensing mechanism is ingeniously integrated within a single-mode optical fiber measuring a mere 125 microns in diameter. The core of its functionality lies in the photoelastic effect, a phenomenon where mechanical disturbances, such as minute vibrations, alter the way light travels through the fiber by changing its refractive index. This optical sensing approach allows for the detection of even the faintest acoustic signals, making it ideal for identifying partial discharge within high-voltage transformers—a critical indicator of impending issues within the power grid. The precision fabrication process, utilizing picosecond laser-induced chemical etching, enables the creation of intricate micro and nanostructures deep within the fiber, ensuring the delicate sensing elements can be integrated seamlessly.

Extreme Environment Performance

The robustness of this all-fiber microphone was rigorously tested, demonstrating its exceptional resilience. During trials, the device was placed inside a furnace operating at 1000°C for an extended period of 100 minutes. Throughout this intense thermal stress, the microphone maintained stable performance and continued to transmit clear, interpretable signals, proving its viability in environments previously inaccessible to electronic sensors. Furthermore, its acoustic detection capabilities were verified across its entire ultra-wide frequency range of 40 kHz to 1.6 MHz, in both air and underwater conditions. The monolithic, self-contained design, with the interferometric structure integrated directly within the fiber, eliminates the need for external protective casings, allowing for straightforward deployment in confined and harsh locations. Future developments aim to incorporate acoustic metamaterials and advanced 3D printing techniques to further enhance sensitivity and mechanical strength, paving the way for long-term deployment in demanding real-world industrial settings.