Rapid Read • 8 min read

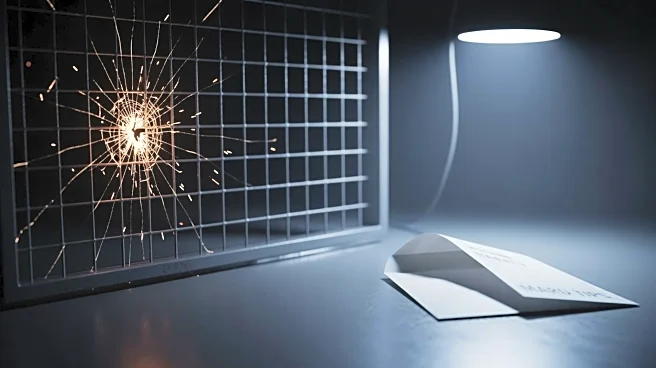

The European Space Agency (ESA), in collaboration with Airbus, has successfully produced the first metal part ever made in space using a 3D printer aboard the International Space Station (ISS). This milestone was achieved in 2024, with samples returned to Earth for analysis in early 2025. The project aims to study the porosity, microstructure, and mechanical properties of space-printed metal compared to Earth-printed stainless steel. The process involves tightly controlling powder containment, gas flow, and laser parameters in microgravity to stabilize the melt and avoid spatter. The initiative is part of a broader effort to reduce dependence on cargo manifests and resupply lead times, crucial for future deep-space operations.

AD

The ability to manufacture metal parts in space represents a significant advancement in autonomous space exploration. It reduces the need for launching spare parts from Earth, potentially lowering costs and increasing efficiency for long-duration missions. This technology could support lunar surface campaigns by complementing in-situ construction methods, thereby lightening mass-to-orbit budgets. The success of this project could pave the way for fabricating structural elements in space, which are too bulky to launch in their final form. The implications extend to faster repairs and a more sustainable approach to building necessary components directly in orbit or on the Moon.

ESA plans to publish lab data, refine the process window, and determine which classes of parts are viable for on-orbit use. The focus will be on ensuring repeatable material properties, tight dimensional tolerances, and safe powder handling. Quality assurance will likely involve non-destructive evaluation techniques and mechanical tests on returned samples. If successful, this could lead to fewer spares launched, faster fixes, and a path toward building essential components in space, supporting future lunar and deep-space missions.

The project highlights the challenges of space additive manufacturing (AM), including vibrations, radiation, thermal swings, and crew time constraints. Microgravity may influence defect formation and residual stress, necessitating post-processing and inspection strategies. The initiative underscores the importance of developing robust quality assurance methods to qualify space-printed parts for operational use, ensuring safety and reliability in critical applications.

AD

More Stories You Might Enjoy