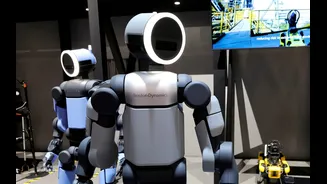

Advanced Agility Unveiled

The recent demonstration of Atlas performing complex gymnastic maneuvers, like a roundoff back-handspring, signifies a major leap in robotic capabilities.

This isn't merely a spectacle for online views; it represents a crucial step towards the widespread industrial deployment of humanoid robots. Unlike the numerous robot mishaps often shared on social media, Atlas showcases a level of dynamic mobility that genuinely captures the attention of industry professionals, particularly those in warehouse management who recognize its potential for real-world operations. This advanced movement signifies a move from novelty to utility, indicating that robots are finally bridging the gap between impressive digital content and tangible, functional tasks in various sectors, promising enhanced efficiency and new operational paradigms.

Engineered for Industry

Atlas is meticulously engineered for rigorous industrial environments, boasting a combination of Olympic-level agility and robust construction, facilitated by its modular design and impressive specifications. Standing at 1.8 meters tall and weighing approximately 85 kilograms, this humanoid robot possesses the strength to lift objects up to 110 pounds, surpassing the safe lifting capacity for many humans. Its modular head integrates 360-degree sensors and onboard computing, while its fully rotatable torso and head joints eliminate the cumbersome movements characteristic of earlier humanoid designs, allowing for fluid and natural motion. The inclusion of removable batteries offers a four-hour operational lifespan and IP67 weatherproofing, ensuring reliable performance even in challenging conditions that would impede human workers. A significant shift from hydraulic systems to all-electric actuators means Atlas operates without fluid leaks and demands minimal upkeep, unlike its predecessors. With 28 to 56 degrees of freedom, it achieves human-like manipulation capabilities without human limitations, operating continuously without the need for breaks, sick leave, or concerns about workplace injuries and associated compensation claims, marking a substantial advancement over consumer-oriented robotic applications.

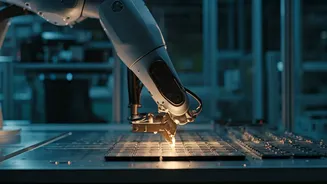

Intelligent Automation Integration

The latest iteration of Atlas embodies a synergy of advanced physical capabilities and sophisticated artificial intelligence, paving the way for its integration into assembly lines and complex industrial settings. Representing Hyundai's manufacturing prowess, this robot is being developed with 'athletic intelligence,' enabling it to perform sophisticated tasks with remarkable adaptability. This intelligence is not just for show; it allows the robots to navigate cluttered environments, adeptly handle irregularly shaped objects, and react to unforeseen obstacles without requiring constant reprogramming. The planned 2026 production timeline is already fully subscribed, with companies eager to deploy these units. The utilization of fleet management software, such as Orbit, allows multiple Atlas robots to share learned skills and operational data, accelerating the development of collective knowledge within an organization far more rapidly than traditional human training methods. While the company emphasizes coexistence and augmenting human capabilities rather than outright replacement, the potential for robots to operate 24/7 without fatigue raises important economic considerations regarding the future of manufacturing jobs.