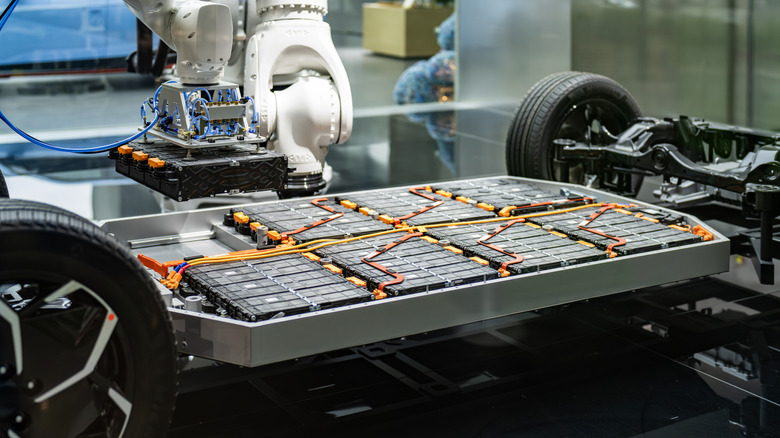

The centerpiece of any electric car is the battery, both in terms of innovation and hazard. However, batteries can sometimes go up in flames, and the risks of them catching fire in closed spaces only raise

the damage potential, though some argue that it's more hype than reality.

Experts at Drexel University claim to have created an ultrasound-based bench tool that can detect faulty batteries before they are deployed and pose a material hazard. The team claims that the methods developed by them "would immediately reveal any damage or flaws that could lead to overheating and even cause thermal runaway," a system breakdown in lithium-ion batteries in which an uncontrolled chemical reaction leads to a sustained rise in temperature levels and also jacks up the pressure levels, leading to leakage of harmful gases, fire, and even explosion.

The current trend in the industry is that a small batch of batteries rolling off the assembly line receives physical examinations and electrical tests to find any flaws. X-ray imaging is also used, but the assessment protocols are not comprehensive. The ultrasound-based approach is claimed to be faster, more affordable, and offers a deeper level of structural insight.

Read more: 10 Car Brands With The Nicest Interiors

A Big Win

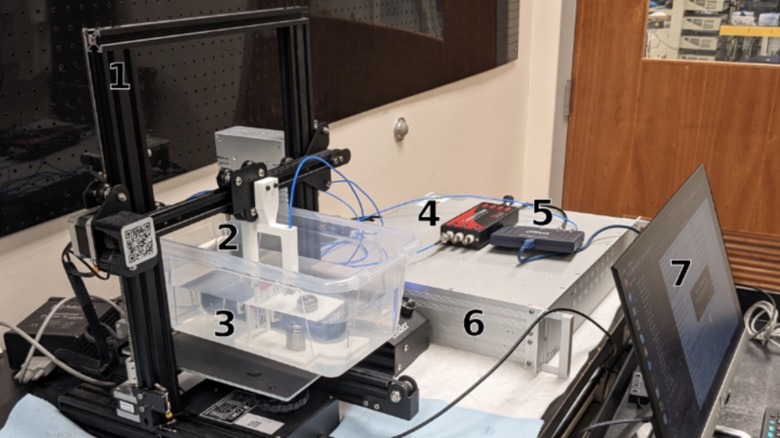

Before we dig into the science behind the proposed method for checking the health of batteries, let's discuss the most notable part of the whole exercise. The team has open-sourced the testing software and the necessary files, which means any company or expert can take advantage of the methodology or even build atop it. Second, the modular machine they propose for checking the health of lithium-ion batteries using sound waves was built using a modified 3D printer and additional parts that can be easily purchased out there.

The whole apparatus can be built for less than $10,000, while the most basic setup (which includes a computer, a pulser, an ultrasonic transducer, and an oscilloscope) should come in just over $6,000. For comparison, a typical lithium battery X-ray inspection machine can cost between $40,000 and $50,000 for large-scale manufacturers and even more in the retail market. But why ultrasonic waves?

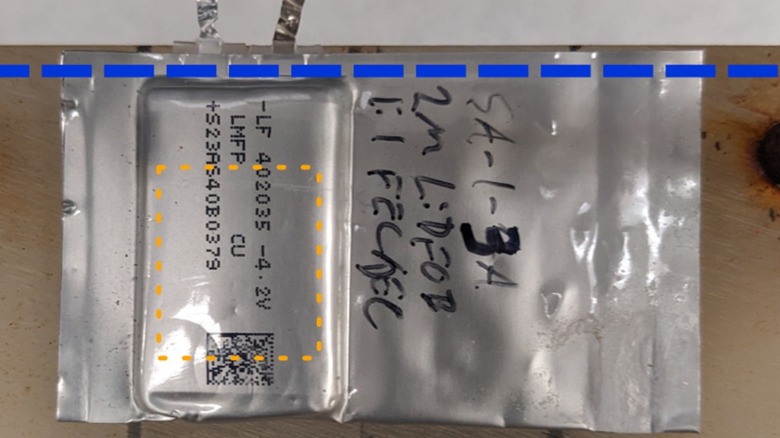

Over the years, automobile engineers and scientists have proposed a variety of solutions. Some of them have shown incredible promise but haven't been implemented at scale yet, while a few of the legacy solutions are doing more harm than good. One of the more promising avenues that has emerged over the past decade has been using sound waves to develop lithium-based batteries. This is the approach being pushed by the scientists at Drexel University to find signs of defects in batteries. The team describes the technique as "scanning acoustic microscopy technology to send low-energy sound waves through a commercial pouch cell battery."

Solving The Gas Problem

The underlying idea is to shoot sound waves through the lithium-ion battery pack. As the waves pass through various materials and layers in the battery, their shape changes, which, in turn, offers researchers a proper look at the structural and mechanical features of the battery. If there are any structural defects or anomalies, the shape of the sound waves is also changed abruptly. The defects could be of various types. It could be a material problem localized to a certain region in the battery, electrical connection issues, or a charge-related imbalance in the electrochemical material that allows the passage of current in the battery pack.

Some of these imperfections may be subtle and not pose an immediate hazard, but over time, they may pose a threat. The most promising aspect of this technique is that it can be deployed at the manufacturing stage, but also for research and safety validation. "One substance the scan is particularly good at detecting is gas, which is important because the presence of gas inside a battery is an indication of dry areas that could cause the cell to fail while it is being used," claims the team.

The presence of gas in a lithium-based battery is not good news. Some of them are flammable and can trigger a thermal runaway event. As per research published in the Energy Reports journal, they can also take a toll on the cell performance by degrading the electrode, reducing the pack's shelf life, and displacing the electrolyte. The low-cost, ultrasonic tabletop device proposed by researchers will help find these risky gas pockets and pave the way for safer batteries fitted inside electric cars.

Want the latest in tech and auto trends? Subscribe to our free newsletter for the latest headlines, expert guides, and how-to tips, one email at a time.

Read the original article on SlashGear.