Many DIY enthusiasts have to contend with electrical wiring eventually in some capacity. The descent into this rabbit hole often begins with the fundamental question: What exactly is a wire gauge, and

why does it matter? Wire gauge, typically measured in AWG (American Wire Gauge) across North America, is the measurement of the thickness or, more precisely, the diameter of the conductive element within the wire. The diameter, or the cross-sectional area, of the conductor matters because it ultimately dictates the amount of current that can be carried safely through the wire.

The AWG standard is a bit counterintuitive because thinner wires have a larger AWG number, whereas the opposite is true for the thicker variety. That means a 4 AWG wire is heavier, broader, and capable of carrying a much larger amount of current compared to its 8 AWG counterpart. The confusing nomenclature originates from the nineteenth-century wire manufacturing process, wherein a wire of a standard diameter is reduced to the desired size by drawing it through a series of progressively smaller dies. The larger the AWG number, the smaller the die diameter, which also causes the wire drawn from it to end up being thinner.

The standard AWG wire sizes can vary from the largest 000 AWG wire that measures in at a diameter of 0.46 inches to something as small as 36 AWG, which is exponentially smaller at 0.005 inches in diameter. The standard goes beyond 36 AWG, but it's uncommon to have wires thinner than 32 AWG even for the smallest electronics projects.

Read more: 6 Smart Gadgets To Help Upgrade Your Garage Or Workshop

Why Bother With Different Wire Sizes?

The electrical resistance of a wire increases with its cross-sectional area, whereas its ampacity (or current-carrying capacity) decreases by the same measure. In practical terms, using an undersized cable to power a device drawing a large amount of current will cause the wire to overheat and the device itself to malfunction due to insufficient amperage. In extreme cases, the conductor can get hot enough to ignite the insulation and become a fire hazard.

That's why wires are rated to carry a certain amount of maximum current, which decreases with the AWG number and increases with the cross-sectional area. For example, a 4 AWG cable is rated at an ample 70A, whereas a 22 AWG cable can only carry a maximum of 3A safely at 60 °C. Power-hungry appliances such as HVAC units and electric car chargers require thick feeder cables (6 AWG to 4 AWG) to handle electrical loads in excess of 30A without overheating.

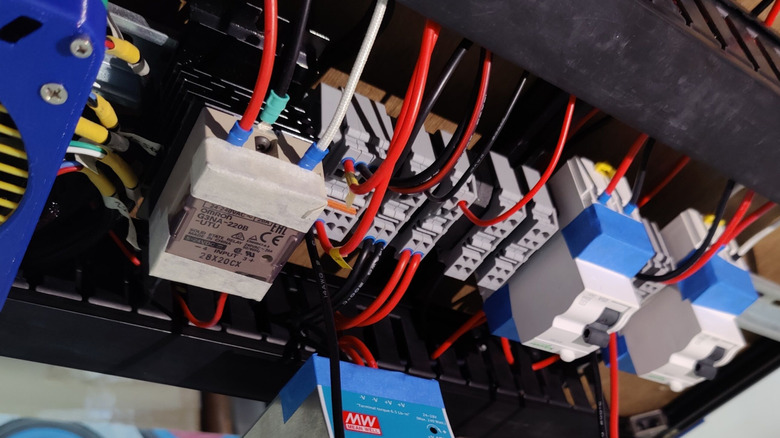

While a 4 AWG cable has enough ampacity to handle almost everything, wasting copper is prohibitively expensive all the same. Because grossly oversized cables are also unlikely to fit through cable conduits and electrical panels, sizing wires efficiently is a must in automotive and aerospace applications where every single gram and millimeter counts. Meanwhile, thinner electrical cables are not only flexible, but they also leave enough room to improve airflow.

A good engineer calculates the electrical load of a system and uses that data to select electrical wires of just the right thickness to power the system safely.

How To Size Electrical Wires Optimally

Sizing electrical wires accurately is serious business when you're trying to find the Goldilocks zone between efficient use of copper at one end of the spectrum and a raging electrical fire at the other extreme. Fortunately, the math underpinning wire gauge selection is a simple matter of adding up the total electrical load to calculate the total current the wire is expected to carry.

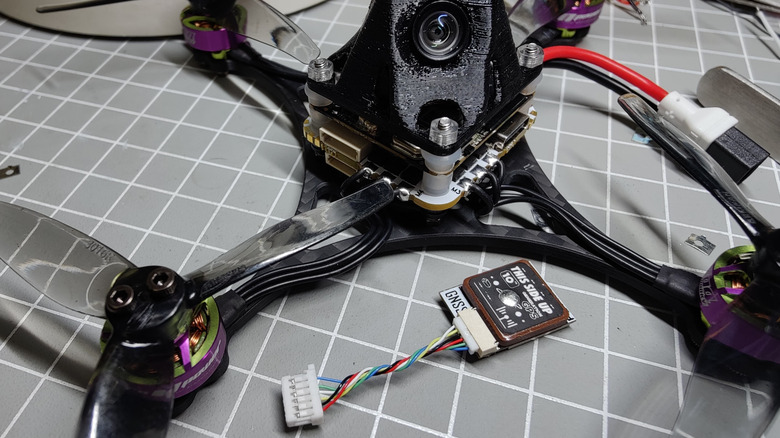

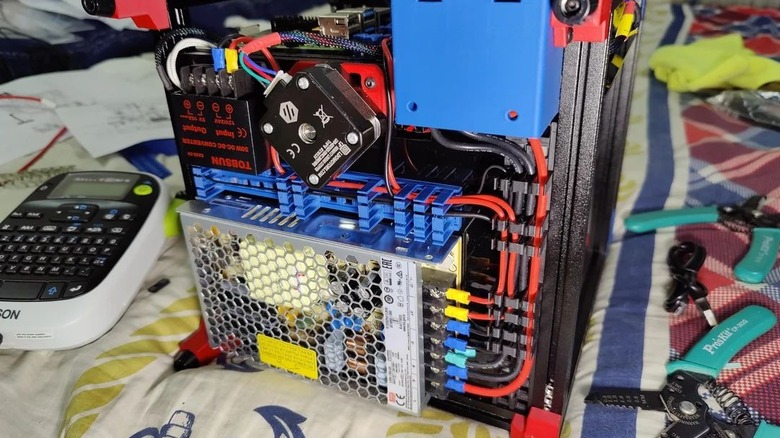

Sizing a cable supplying power to a kitchen circuit, for example, calls for calculating the collective maximum power draw of all kitchen appliances in the circuit. The same logic applies to a smaller DC application like an FPV drone, where determining the battery cable gauge is a matter of calculating the cumulative maximum power draw of the motors powering the craft.

The next step involves calculating the maximum current expected to flow through the wire under consideration. This is achieved by dividing the total calculated power draw by the voltage of the circuit. Let's consider the example of a typical 3.5-inch freestyle FPV drone powered by a 16-volt LiPo battery, which typically draws 800 watts maximum. This gives us a current requirement of 50A for our battery leads.

However, our job doesn't end at selecting the wire gauge that is rated for your maximum current requirement. In the real world, a wide variety of factors ranging from the material properties of the wire itself to the environmental variables governed by the nature of the deployment dictate the size and choice of the cable. Let's take a closer look at how that works.

How Wire Gauge Affects Voltage Drop

The equipment connected to electrical cables is expected to be supplied with voltage in a certain specified range. Falling short or exceeding this narrow supply voltage range leads to unpleasant consequences. Mistakes in cable selection often result in voltage drops, which can cause problems ranging from dim lights and underperforming heaters to malfunctioning electronics and burnt motors. That's why engineering bodies such as IEEE set a maximum threshold for voltage drop at 2.5% of the supply voltage at any point in the circuit.

Knowing the factors causing voltage drops is key to figuring out how to stay within the safe voltage drop threshold. The electrical conductivity of the material used in the cable is the key factor governing voltage drop. The higher conductivity of copper wires allows them to experience reduced voltage drop compared to their aluminum counterparts.

However, that approach is moot for practical purposes because most electronic circuits and residential as well as commercial electrical circuits employ copper wires. When the wire material remains unchanged, increasing the cross-sectional area is one way to mitigate voltage drop. The ensuing reduction in electrical resistance offered by the larger gauge wire also reduces the severity of voltage drop experienced by the connected loads.

The total length of the cable run is another key factor affecting resistance and, consequently, voltage drop as well. Optimizing the electrical circuit to minimize wire runs makes it easy to hit your voltage drop goals. Deciding whether to increase the wire gauge and/or reduce cable length — and by how much — is best done with the help of a voltage drop calculator.

What Are Deratings And How That Affects Wire Gauge Selection?

Choosing the right wire gauge doesn't end at calculating voltage drop and ampacity parameters. Various environmental factors governed by the nature of the application often warrant radical changes to the type and thickness of the wires needed to ensure safe power delivery. Temperature deratings often apply to electrical applications, such as electrical cables passing through the attic or those situated in the engine bay, because the current-carrying capacity of wires decreases with an increase in the ambient operating temperature.

The converse is true as well. Fast flying FPV drones, for example, often use relatively thin wires to carry a massive amount of current from high-discharge LiPo batteries due to the ample cooling available as these drones cut through the air. While you may refer to the National Electrical Code (NEC) tables to calculate such temperature deratings, free online calculators make it easy to calculate effective ampacity by punching in relevant parameters like insulation temperature rating, ambient operating temperature, and the number of strands within the wire.

Spatial limitations on bundling of conductors within a raceway also contribute to ampacity deratings. The NEC discourages passing more than three current-carrying conductors through a raceway, cable, or buried in the earth. Exceeding this number limits the cables to 80% of their rated ampacity for bundles of four to six conductors, with the 7-9 conductor bundles incurring an additional 10% derating. Your choice of cable gauge must therefore be tempered by these environmental deratings, with an additional 20% to 30% headroom factored in for safety and future expansion.

Want the latest in tech and auto trends? Subscribe to our free newsletter for the latest headlines, expert guides, and how-to tips, one email at a time.

Read the original article on SlashGear.