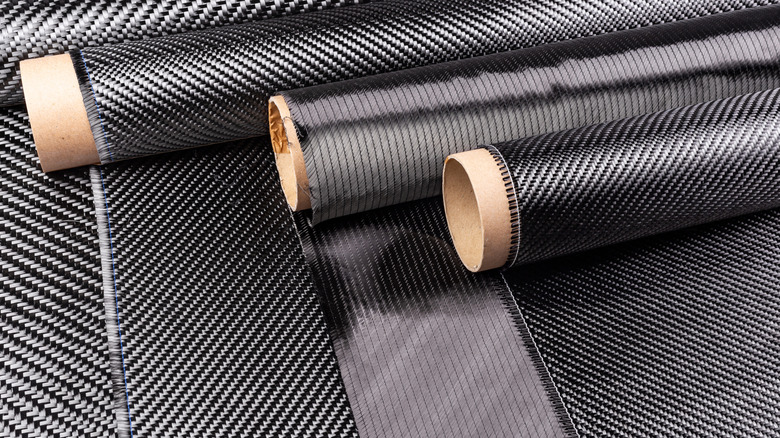

Carbon fiber is one of the most impressive materials out there. It is stronger than steel, yet so lightweight that it's used in everything from airplanes and tough parts for supercars to high-end bikes

and tennis rackets. Its strength-to-weight ratio is unmatched, which makes it a go-to for industries that care about performance and efficiency. With more carbon fiber products being manufactured than ever before, the question of what happens to all this material at the end of its life is becoming more important.

Yes, carbon fiber can be recycled, but the process is far from simple. While recycling helps reduce environmental waste and greenhouse gas emissions, the challenges in breaking down and reclaiming carbon fiber make it a complicated, costly, and often limited practice.

In most cases, the quality of recycled fiber isn't quite good enough for high-performance industries, so it gets downcycled into lower-grade products. That's just one of the many problems with carbon fiber.

Read more: 9 Cheap Cars That Look Expensive

Why Carbon Fiber Recycling Is So Difficult

The biggest hurdle in recycling carbon fiber lies in separating the fibers from the hardened plastic resin that holds them together. Traditional recycling methods like shredding or burning can extract the fibers, but they often damage them in the process.

That damage makes the recycled fiber weaker and unsuitable for use in sectors like aerospace or high-performance automotive, where strength is everything. This degradation limits its value and restricts it to lower-end applications, like construction materials or consumer goods.

Even with advanced thermal processes, recycling carbon fiber is energy-intensive and expensive. These systems can burn through large amounts of electricity and heat, and only a few specialized facilities in the world can handle the job at scale.

As a result, most carbon fiber waste still ends up in landfills, despite being non-biodegradable and capable of lingering in the environment for over 50 years. More than 30% of carbon fiber material is wasted during manufacturing alone, which adds up quickly, especially in industries that use it in bulk.

The Push Toward Smarter Recycling

Thankfully, newer recycling techniques are offering a way forward. Chemical recycling, for example, avoids the heat damage by breaking down the resin chemically and allowing the carbon fibers to stay nearly as strong as when they were first made.

Researchers at USC even developed a method that keeps over 97% of a fiber's strength while also reclaiming the valuable polymer matrix. Other innovations, like using engineered fungi to break down composite materials, are showing promise too.

Still, cost remains a major roadblock. New carbon fiber is up to 20 times more expensive than steel, and recycled fiber, while cheaper by 30–40%, still faces quality concerns. However, with demand for sustainable materials on the rise, along with growing pressure to deal with future waste from wind turbines and aircraft, companies and researchers are doubling down.

Some startups are working on new polymers that allow reshaping old parts while cutting down on the processing time and cost. It's clear that if the industry can scale up these solutions, recycled carbon fiber could help bridge the growing supply gap.

Want the latest in tech and auto trends? Subscribe to our free newsletter for the latest headlines, expert guides, and how-to tips, one email at a time.

Read the original article on SlashGear.