While the World War II era was the first time we saw fighter jet engines take to the sky, there were some earlier operational prototypes. Anselm Franz, an Austrian engineer, designed and fitted one of

the earliest jet engines, the Jumo 004, into the Messerschmitt Me 262, becoming the first mass-produced turbojet aircraft with a jet engine. It was a narrow-intake, single-stage axial turbine engine, and, by our modern standards, it was small.

It was less than 13 feet long, about 8 feet wide, roughly 3 feet tall, and weighed only 1,630 pounds. These were large dimensions at the time because the U.S.'s response to the Me 262, the Lockheed P-80 Shooting Star, was originally fitted with H-1 Goblin turbojet engines, and that was about 9 feet long, 4.5 feet wide, and weighed 1,500 pounds.

It didn't take long after the war for these dimensions to double. First, jet engines for warplanes got bigger, and commercial jet engines for wide-body airliners followed the trend. And they've gotten bigger because bigger engines actually improve efficiency and save airlines money.

Read more: 10 Airplanes That Managed To Fly With Staggeringly Low Horsepower

What Happened To Jet Engines After World War II

By 1950, we had Pratt & Whitney J57 engines that were over 13 feet long and weighed well over 4,000 pounds. There was no longer a great need for planes with short service lives. People needed engines that could withstand more pressure, higher temperatures and go for longer ranges as reconnaissance and Cold War tactics became the priority. That meant the engines coming out of the factories needed beefier materials and more complicated parts -- this led to more weight and bigger turbofans.

Of course, it was these sturdier engines and efficient variations that eventually made their way into Boeing 707 commercial transport jets. The Boeing 747, known as the Queen of the Skies, appeared two decades later, fitted with the JT9D turbofan engine that delivered 53,000 pounds of thrust to handle all the extra weight. The engine had a naked weight of 9,155 pounds, which was unprecedented at the time.

Today's jet engines are now larger than ever, especially on modern wide-body aircraft, like the Boeing 777 and 787. General Electric's GE90, which powers many 777s, has a maximum engine diameter of over 11 feet, which, for context, is only about 1 foot less than a Boeing 737's fuselage, and can produce up to 115,000 pounds of thrust.

The Science Behind Why Jet Engines Are Getting Bigger

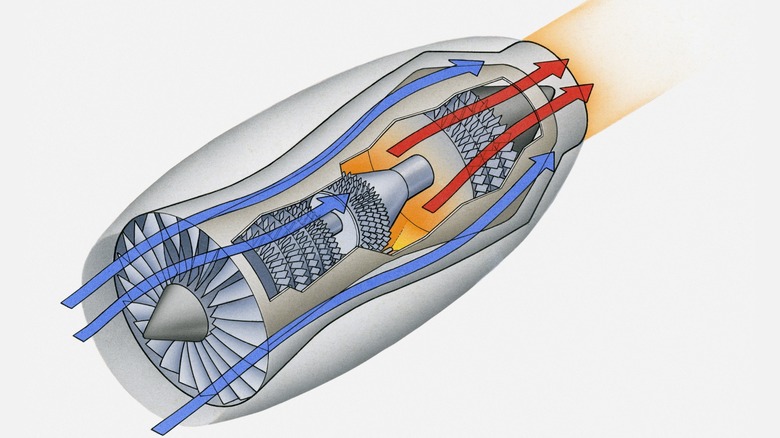

The main reason why jet engines have gotten bigger is that larger engines are more efficient than smaller ones. There are two important aspects of efficiency here: turbofans and bypass ratio. When a jet engine sucks in air for combustion, only a small portion of that air goes into the engine core, the bulk of it goes around instead, and the turbofan is what draws in the air. The amount of air bypassing the core versus going through it is what's known as the bypass ratio.

The effect of a high bypass ratio is that the engine throws a large amount of air more slowly instead of shooting a small amount of gas really fast (like in early turbojets). That means the plane can generate more thrust with less fuel. Larger turbofans allow in even more air, and that's why the engines keep getting even bigger and bigger. Commercial airliners are often working with razor-thin margins. Therefore, they are always trying to figure out ways to save on fuel, one of their major expenses. Modern wide-body jets, like the Boeing 747 and Airbus A380, need even bigger engines to muster enough thrust to get these enormous aircraft off the ground.

Normally, big engines might mean more weight and less efficiency, but material science has improved since jet engines were invented in the '40s. There are composite fan blades and lightweight alloys that let engineers build bigger engines without the literal drag of additional weight.

Want the latest in tech and auto trends? Subscribe to our free newsletter for the latest headlines, expert guides, and how-to tips, one email at a time.

Read the original article on SlashGear.